What Makes a Good Precision Mold Core Insert Manufacturer Stand Out?

In the highly competitive world of manufacturing, choosing the right precision mold core insert manufacturer can be the key to success. Mold core inserts are critical components in the injection molding process, ensuring that parts are produced with the highest precision, durability, and efficiency. But what truly sets a good manufacturer apart? In this article, we'll explore the essential qualities that make a precision mold core insert manufacturer stand out from the crowd, focusing on expertise, technology, and customer service.

1. Expertise and Experience in Precision Mold Core Inserts

A leading precision mold core insert manufacturer is distinguished by their extensive expertise and years of experience in the industry. Manufacturers who specialize in mold core inserts understand the nuances of different materials, design complexities, and the specific needs of various industries. Experienced suppliers can offer custom solutions, ensuring the inserts are designed to match the specifications of your molds, leading to high-precision parts.Additionally, a reputable parts mold cavity core insert supplier has experience working with a variety of industries, from automotive to electronics, ensuring they understand the unique challenges and requirements of each sector.

2. Advanced Technology and Equipment

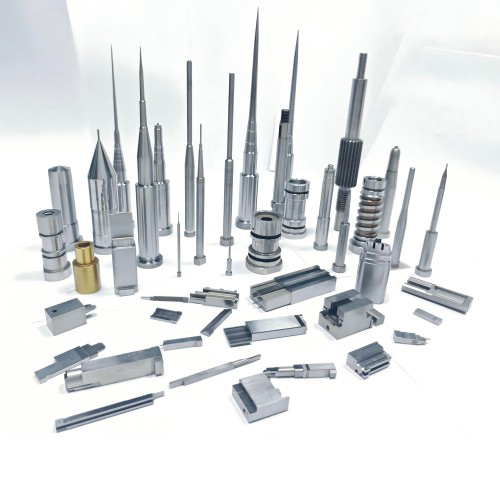

To ensure the highest level of precision, mold insert machining suppliers must utilize state-of-the-art equipment. CNC machining, EDM (Electrical Discharge Machining), and other advanced technologies are essential for producing inserts that meet the tight tolerances required in today’s manufacturing processes. Manufacturers that invest in advanced machinery can offer faster turnaround times, improved accuracy, and longer-lasting mold core inserts.This investment in technology also translates to the ability to produce complex geometries and intricate designs that would be challenging with outdated methods. By partnering with a technologically advanced manufacturer, you gain access to innovation and efficiency that can improve your overall production process.

3. Customization and Flexibility

A standout precision mold core insert manufacturer should offer a high degree of customization. This includes the ability to work with a variety of materials (such as hardened steel, aluminum, or specialty alloys) and the flexibility to meet the specific dimensions and design requirements of your project. Customization ensures that your mold inserts fit seamlessly into your production line, reducing downtime and enhancing efficiency.Good manufacturers will also collaborate closely with their clients during the design and production process, ensuring that the final product meets exact specifications. Whether you need custom mold core inserts for a specialized project or bulk orders for mass production, the best suppliers provide flexible solutions that cater to your unique needs.

4. Quality Assurance and Consistency

Consistency in product quality is non-negotiable when it comes to parts mold cavity core insert suppliers. Top manufacturers implement rigorous quality control processes to ensure each insert meets high standards of precision and durability. This includes thorough inspection protocols, such as dimensional checks, hardness testing, and surface finish analysis.By partnering with a manufacturer that prioritizes quality assurance, you can trust that your mold core inserts will perform consistently across production cycles, reducing the risk of defects and rework.

5. Timely Delivery and Customer Support

In today’s fast-paced manufacturing environment, timely delivery is critical. Leading mold insert machining suppliers have efficient supply chains and production schedules, ensuring that orders are completed and delivered on time. This reliability is particularly important when working with tight deadlines or high-volume orders.

Furthermore, exceptional customer support distinguishes a good manufacturer. Whether you need technical advice, assistance with a custom design, or help resolving an issue, responsive customer service ensures a smooth and efficient working relationship.

6. Cost-Effectiveness and Long-Term Value

While cost is always a factor, the best precision mold core insert manufacturers focus on delivering long-term value rather than just offering the lowest price. High-quality mold inserts may require a higher initial investment, but they offer greater durability, longer lifespan, and lower maintenance costs, providing better overall value for your business. Working with a manufacturer that balances competitive pricing with exceptional product quality ensures you get the most out of your investment.

In conclusion, choosing the right precision mold core insert manufacturer involves considering their expertise, technology, flexibility, and commitment to quality. By partnering with a reliable supplier, such as one of the top mold insert machining suppliers or parts mold cavity core insert suppliers, you can enhance your production efficiency, reduce costs, and ensure consistent product quality.Look for manufacturers that combine technical expertise with a strong focus on customer service and quality assurance, ensuring your manufacturing process runs smoothly and efficiently.

Precision mold core insert manufacturers mold insert machining suppliers parts mold cavity core insert suppliers