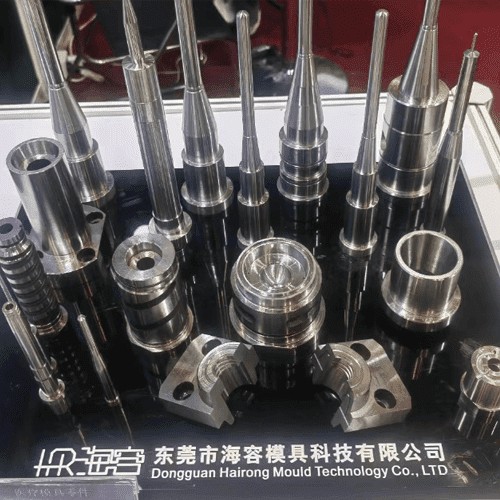

Manufacturing Mold Core And Cavity Insert Guideline

In the world of precision manufacturing, core and cavity inserts play a crucial role in creating complex molded parts. These inserts, which form the internal and external shapes of molded products, are key to achieving accuracy, durability, and efficiency in the injection molding process. Whether you’re a manufacturer or a business seeking custom solutions, understanding the ins and outs of custom mold core and cavity inserts is essential.

1. What Are Core and Cavity Inserts?

Core and cavity inserts are specialized components of a mold that shape the interior (core) and exterior (cavity) of a part during the injection molding process. These inserts are engineered to withstand high pressures and temperatures, ensuring the creation of precise, high-quality molded products. For companies that need specific, detailed designs, custom mold core and cavity inserts are the go-to solution.

2. Benefits of Custom Mold Core and Cavity Inserts

Choosing custom mold core and cavity inserts comes with several benefits. Custom inserts are tailored to meet exact specifications, allowing for high precision and improved product consistency. Additionally, they offer flexibility in design, which is particularly advantageous when manufacturing parts with intricate or unique shapes.

For businesses seeking custom mold core and cavity inserts for sale, this customization also ensures that molds fit their specific production needs, reducing downtime and increasing efficiency.

3. Why Opt for Wholesale Custom Mold Core and Cavity Inserts?

Buying custom mold core and cavity inserts wholesale is a cost-effective approach for manufacturers with large-scale production requirements. Wholesale orders provide the opportunity to secure high-quality inserts at competitive prices, enabling businesses to maintain consistent production without compromising quality. By opting for bulk purchasing, companies can also reduce lead times, ensuring a steady supply of inserts for uninterrupted production.

4. Factors to Consider When Selecting Core and Cavity Inserts

When choosing custom mold core and cavity inserts, several factors come into play:

Material: The material of the insert must be durable enough to withstand the injection molding process. Common materials include hardened steel and aluminum.

Precision: Ensure the inserts are manufactured with high precision to meet the design specifications of your products.

Compatibility: Custom inserts must be compatible with your existing mold setup to ensure seamless operation.

Supplier: Working with a reputable strobe lights supplier is essential to guarantee the quality and longevity of the inserts.

5. Where to Find Custom Mold Core and Cavity Inserts for Sale

There are numerous suppliers offering custom mold core and cavity inserts for sale, but it’s crucial to select a partner that can deliver high-quality inserts at competitive prices. Look for a supplier with a strong track record, excellent customer service, and the ability to meet your production timelines. Many suppliers also offer customization options, allowing you to tailor the inserts to your specific needs.

In conclusion, custom mold core and cavity inserts are an essential component in the injection molding process, providing precision, efficiency, and flexibility. Whether you’re purchasing custom mold core and cavity inserts wholesale or just starting to explore your options, understanding these inserts and their benefits will help you optimize your manufacturing process and improve overall productivity.

core and cavity inserts Custom mold core and cavity inserts Custom mold core and cavity inserts for sale Custom mold core and cavity inserts wholesale