How Do Precision Molding Parts Improve Product Performance?

Precision is everything when it comes to manufacturing high-quality products. Whether you're producing components for medical devices, automotive parts, or consumer electronics, precision molding parts play a critical role in improving performance. But how exactly do these finely crafted components make such a big difference? Let’s break it down.

1. Perfect Fit, Every Time

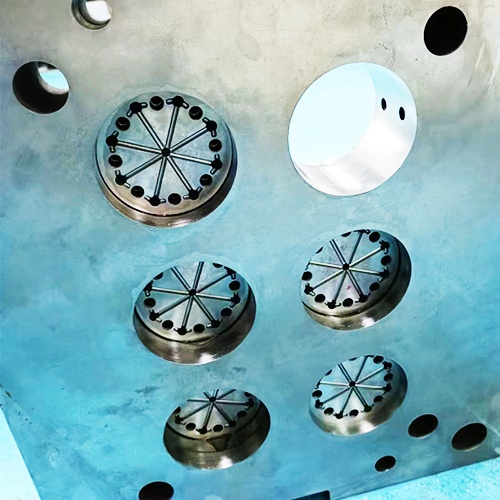

Imagine assembling a product, and one piece doesn’t quite fit. Even a slight mismatch can lead to malfunction or reduced product efficiency. With precision molding parts, this problem is virtually eliminated. These parts are manufactured with extreme accuracy, ensuring they fit perfectly into your product assembly, down to the micron level.Companies specializing in china precision mold components use advanced machinery and technology to ensure every part is made to exact specifications, ensuring consistent performance from one product to the next.

2. Durable Materials, Long-Lasting Results

Durability matters, especially in high-stakes industries like automotive and aerospace. Precision molding parts can be created using high-strength materials like advanced polymers or specialized metals. This makes them highly resistant to wear and tear, even under harsh conditions.For example, a customized precision mold components factory can offer tailored material options that meet your product’s specific needs, from heat resistance to corrosion protection. As a result, your products will last longer and perform better over time, giving your brand a reputation for reliability.

3. Less Waste, More Efficiency

In the world of precision molding, waste is the enemy. One of the biggest advantages of working with a precision mold components manufacturer is their ability to minimize waste. With precise molds, manufacturers use just the right amount of material for each part, which not only saves costs but also supports more sustainable production processes.Plus, high-precision manufacturing means fewer errors, less need for rework, and a more streamlined production line. This results in faster turnarounds and lower costs overall, making your manufacturing process far more efficient.

4. Customization for Unique Needs

When off-the-shelf parts just won’t cut it, customization is the answer. Many customized precision mold components factories offer bespoke solutions, tailoring each component to meet specific product requirements. This is especially crucial in sectors like medical devices, where even the smallest deviation from design could impact the safety or functionality of the product.With custom precision molding, you get parts designed exactly for your application, ensuring optimal performance. Whether it’s a unique geometry or specific material requirement, customization allows manufacturers to push the limits of innovation.

5. Aesthetic Appeal and Functionality

It’s not just about the internal workings of your product—sometimes, the look and feel matter just as much. Precision molding offers superior surface finishes, allowing manufacturers to create sleek, polished components that add aesthetic value to the product. Think about high-end consumer electronics where appearance is part of the selling point.Functionally, complex geometries achieved through precision molding can enhance airflow, reduce friction, or improve heat dissipation. These subtle improvements can dramatically boost a product’s overall performance.

6. Built for Long-Term Reliability

When your product’s performance is on the line, long-term reliability is essential. Precision molding parts are designed to meet stringent quality standards, ensuring they remain functional over extended periods. Sourcing from a trusted China precision mold components supplier guarantees that the parts are produced using state-of-the-art technology and adhere to industry certifications like ISO.Reliability isn't just a perk—it's a requirement in industries like aerospace and automotive, where a part failure can be catastrophic. By choosing high-quality precision components, you're ensuring that your products maintain their performance and safety standards for years to come.

Precision molding parts are not just a small part of the manufacturing process—they are the foundation of superior product performance. From perfect fits and durable materials to custom designs and reliability, these components make all the difference in taking your product from good to exceptional. By partnering with a customized precision mold components factory, you can ensure your products achieve the performance levels your customers expect.Whether you need parts for medical devices, electronics, or automotive components, precision molding delivers on both quality and efficiency. The result? Products that perform better, last longer, and exceed customer expectations.

precision molding parts china precision mold components cusotomized precision mold components factory