How to Compare Precision Mould Part Manufacturers for Quality?

Choosing the right precision mould part manufacturer is crucial for ensuring the success of your project. With so many options available, it can be challenging to identify which manufacturer will deliver the highest quality precision molding parts that meet your specific needs. To make an informed decision, you must evaluate key factors that directly impact the quality and reliability of the precision injection moulding parts you are purchasing.In this article, we will guide you through the essential steps to compare manufacturers and help you select the best supplier for high precision injection molding parts.

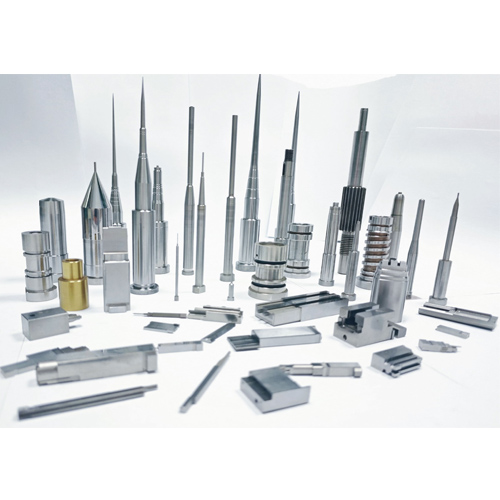

1. Material and Manufacturing Capabilities

The first step in comparing precision mould part manufacturers is assessing their material expertise and manufacturing capabilities. High-quality precision mould parts require the right material selection, which directly affects the durability and performance of the final product. Leading manufacturers often offer a variety of materials such as steel, aluminum, or custom alloys tailored for different industries. Be sure to ask about their experience with specific materials and whether they can meet the exacting standards required for your project.Additionally, verify if the manufacturer is equipped with advanced technology for high precision injection molding. Modern CNC machines, automated systems, and high-end tooling ensure consistency and tight tolerances, which are vital for precision applications.

2. Quality Control Processes

One of the most critical aspects of comparing manufacturers is their quality control system. A reputable precision mould part manufacturer should have robust quality control measures in place at every stage of production. Ask about their inspection protocols, whether they use automated inspection tools such as coordinate measuring machines (CMMs), and how often they perform quality checks.

ISO certifications, such as ISO 9001, are strong indicators of a manufacturer’s commitment to maintaining high-quality standards. Make sure the manufacturer complies with industry certifications and has a track record of producing reliable precision molding parts that meet stringent specifications.

3. Technical Expertise and Customization

Another key factor is the manufacturer’s technical expertise and ability to provide customized solutions. Not all projects are the same, and you may require specialized precision injection moulding parts tailored to your unique requirements. Look for manufacturers who have experience with complex designs and the capability to offer custom molds with tight tolerances.Also, inquire about their engineering support. A manufacturer with an in-house engineering team can offer valuable insights, helping optimize part design, tooling, and material selection for better performance and cost-efficiency.

4. Lead Time and Flexibility

Quality isn't just about the final product—it's also about the process. When comparing manufacturers, consider their ability to meet deadlines without compromising quality. Lead time can vary significantly between precision mould part manufacturers, and a company with flexible production schedules is more likely to accommodate urgent or changing requirements.Ensure the manufacturer has a clear production timeline and the capacity to scale up or adjust their processes based on your business needs. On-time delivery is a vital part of maintaining smooth operations, especially when dealing with high-demand industries like automotive or electronics.

5. Customer Service and After-Sales Support

Customer service is another aspect that distinguishes top-tier manufacturers from the rest. A reliable precision mould part manufacturer should provide clear communication, timely responses, and consistent support throughout the project. Additionally, consider whether they offer after-sales services such as maintenance, repair, or future mold adjustments, which can add long-term value to your partnership.

6. Industry Experience and Reputation

Finally, a manufacturer’s industry experience and reputation can offer great insights into the quality of their work. Check their client testimonials, case studies, and past projects to gauge their expertise. A manufacturer with a proven track record in delivering high precision injection molding parts for sectors such as aerospace, medical, or automotive industries is more likely to meet high standards.Experienced manufacturers are better equipped to handle complex projects and unexpected challenges, ensuring you receive high-quality parts that perform reliably in demanding environments.

Selecting the right precision mould part manufacturer is a crucial decision that impacts the quality of your products and the success of your project. By carefully evaluating their material capabilities, quality control processes, technical expertise, lead time, and customer service, you can confidently choose a manufacturer who can deliver superior precision molding parts tailored to your needs. Focus on manufacturers with a proven reputation for quality and precision, and you’ll ensure your business gets the best possible results.

precision mould part manufacturer precision molding parts precision injection moulding parts high precision injection molding