How to Effectively Prevent Precision Mold Components from Rusting?

As many of us know, when precision mold components rust, it can be a costly and troublesome issue for manufacturers. Rust not only shortens the lifespan of these components but also affects their durability and performance. Therefore, preventing rust is essential to maintaining the efficiency and longevity of precision mold parts. So, how can you effectively prevent mold components from rusting? Let’s explore some practical methods below:

1. Turn Off Water and Equipment During Production

One of the leading causes of rust in high-precision mold components is improper water handling during production. If water accumulates due to improper operation, rust is inevitable. The key solution is to shut off the machine and water system when not in use. This simple practice can significantly reduce the risk of rust forming.

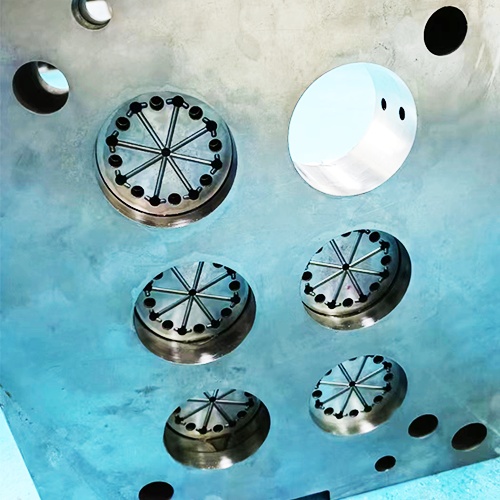

2. Correct Use and Regular Maintenance

Proper use of high-precision mold components is another crucial factor in preventing rust. When the mold stops working, it’s essential to take protective measures by applying rust-prevention oil to the components. Routine maintenance ensures that the parts remain rust-free and in optimal working condition, extending their lifespan.

3. Address Rust Early

If only a small amount of rust is present, it can be removed using abrasive stones. However, if the rust is severe, the affected component should be replaced. Keeping the mold parts in good working order by addressing rust early can prevent long-term damage and ensure smooth operations.

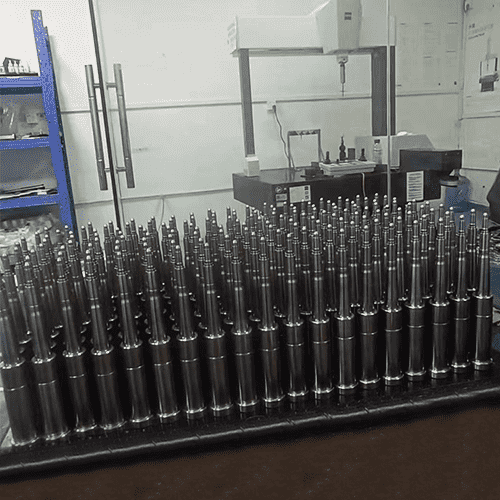

4. Store Components in Dry, Ventilated Areas

Even the best rust inhibitors won’t help if the high-precision mold components are stored in a damp environment. After removing mold parts from the injection molding machine, ensure they are stored in a dry, well-ventilated space. A mold rack in a controlled environment will prevent moisture build-up and rust, even over long-term storage.

5. Wait for Components to Cool Before Applying Rust Inhibitor

Applying rust inhibitor before the mold has cooled can lead to rust within a few days. This is because the mold absorbs moisture from the rust inhibitor while it's still warm, leading to rust formation. It’s important to wait for the mold components to cool down naturally before applying any rust-prevention treatments.

In conclusion, preventing rust on mold components requires a combination of correct usage, regular maintenance, and proper storage. By following these preventive measures—shutting down water systems, applying rust-prevention oils, addressing minor rust early, ensuring proper storage, and waiting for parts to cool before applying inhibitors—you can effectively extend the life of your mold components and avoid costly replacements.

High-precision mold components precision mold components precision mold components company