How to Improve the Surface Quality of Mold Components

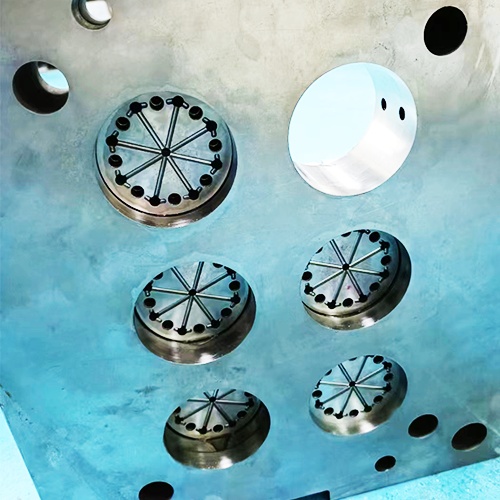

In the mold industry, precision mold componentsare crucial for the performance of stamping molds, plastic molds, or FA automation equipment. Ensuring high surface quality for these high precision components is essential for achieving optimal performance and durability. Here’s how to enhance the surface quality of mold components:

1. Quality of Component Processing and Assembly

The quality of a machine depends heavily on the processing and assembly of its parts. This involves two main aspects: processing accuracy and surface quality.

Processing Accuracy: This refers to how closely the actual geometric parameters (dimensions, shape, and position) of the machined part match the ideal geometric parameters. The difference between these parameters is known as processing error. The smaller the error, the higher the processing accuracy. Key factors influencing processing accuracy include:

- Dimensional Accuracy: How closely the actual dimensions of the part align with the tolerance zone of the part's dimensions.

- Geometric Tolerances: Precision in the part’s shape and position relative to the design specifications.

Assembly Quality: Proper assembly of machined components is crucial. Misalignment or improper fitting can lead to issues with the final mold's surface quality and functionality.

2. Surface Quality of Machined Components

Surface quality involves how well the actual surface dimensions, shape, and position of the machined part conform to the ideal specifications provided in the design. Key factors affecting surface quality include:

- Surface Roughness: Achieved through processes like grinding, polishing, and honing. Smooth surfaces are essential for reducing friction and wear during the mold’s operation.

- Surface Finish Techniques: Employing advanced techniques such as electroplating or coating can enhance surface quality and provide additional protection against wear and corrosion.

3. Position Accuracy of Machined Components

Position accuracy refers to the precision of the relative positions between different surfaces of a machined part. It is crucial to control shape errors within positional tolerances, ensuring that:

- Shape Tolerances: Should be controlled within positional tolerances to maintain overall accuracy.

- Positional Tolerances: Should be stricter than dimension tolerances, meaning that the positional accuracy of critical surfaces should exceed the required dimension accuracy.

Conclusion:

Improving the surface quality of mold components involves a comprehensive approach that includes ensuring high processing accuracy, maintaining excellent surface finishes, and adhering to strict position tolerances. By focusing on these aspects, manufacturers can enhance the performance and durability of molds, ultimately leading to better production outcomes and extended tool life. For those in the mold industry, consistently applying these principles will result in superior mold components that meet the highest standards of quality and precision.

high precision components precision parts manufacturing precision mould part manufacturer