How to Control Aluminum Alloy Die-Casting Mold Temperature?

Controlling the temperature of aluminum alloy die-casting molds is crucial for achieving high-quality castings and maintaining the efficiency of the die-casting process. Temperature regulation not only affects the integrity of the castings but also influences the longevity of the molds and the overall production costs. Here’s a comprehensive guide on how to effectively manage mold temperature, incorporating insights from leading die casting mould manufacturers, aluminum alloy die casting molds for sale, and die casting mould suppliers.

1. Understanding Mold Temperature in Die Casting

The temperature of the die-casting mold plays a significant role in determining the quality of the final product. For aluminum alloy die-casting, maintaining optimal mold temperature is essential to ensure proper metal flow, reduce defects, and improve surface finish. Overheating or insufficient heating can lead to issues such as incomplete filling, warping, and poor mechanical properties.

2. Key Methods for Controlling Mold Temperature

A. Heating Systems

- Electric Heaters: These are commonly used to maintain mold temperature, especially in larger setups. Electric heaters provide precise temperature control and are relatively easy to install.

- Hot Water Circulation: This method involves circulating hot water through channels in the mold to achieve uniform heating. It is particularly effective for maintaining a steady temperature.

B. Cooling Systems

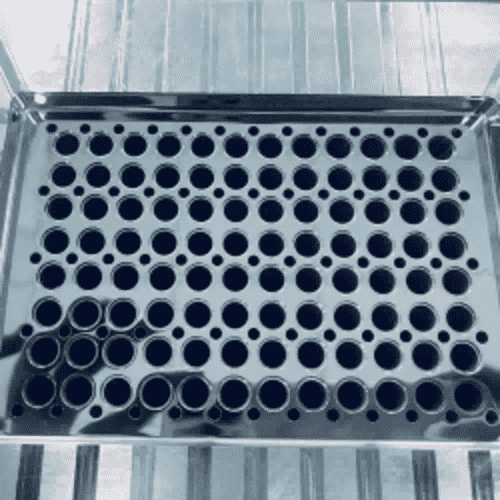

- Water Cooling: To prevent overheating, water cooling systems are integrated into the mold. By circulating cool water through internal channels, you can effectively manage mold temperature and prevent excessive heat buildup.

- Air Cooling: For smaller molds or less intensive cooling needs, air cooling can be an effective solution. This method involves using fans or air jets to dissipate heat.

C. Temperature Control Units

- Thermostats and Sensors: Accurate temperature measurement and control are achieved through thermostats and temperature sensors. These devices provide real-time data and allow for precise adjustments to maintain optimal mold temperature.

- Temperature Controllers: Advanced temperature controllers can automate the heating and cooling processes, ensuring that the mold remains within the desired temperature range throughout the casting cycle.

3. Choosing the Right Die Casting Mold Supplier

When selecting a die casting mould supplier, consider those that offer comprehensive support for temperature control systems. Suppliers who provide aluminum alloy die casting molds for sale should have expertise in integrating effective temperature control mechanisms into their molds. High-quality suppliers will offer molds designed with advanced cooling and heating channels, ensuring efficient temperature management.

4. Maintaining Mold Temperature for Optimal Performance

Regular maintenance and calibration of temperature control systems are essential to ensure consistent mold performance. Frequent checks and adjustments based on real-time data help in preventing temperature-related issues and prolonging the life of the mold.

5. The Impact of Proper Temperature Control

Proper mold temperature control results in numerous benefits, including:

- Improved Casting Quality: Consistent temperature helps in achieving precise dimensions and surface finishes, reducing defects and rework.

- Enhanced Mold Longevity: By avoiding excessive heat or cold, you minimize the wear and tear on molds, extending their operational lifespan.

- Increased Efficiency: Efficient temperature management reduces energy consumption and enhances overall production efficiency.

Conclusion:

Controlling the temperature of aluminum alloy die-casting molds is critical for producing high-quality castings and optimizing production efficiency. By employing effective heating and cooling systems, using advanced temperature control units, and partnering with reputable die casting mould manufacturers and die casting mould suppliers, you can ensure optimal mold performance. Proper temperature regulation not only improves the quality and durability of your castings but also enhances the overall efficiency of the die-casting process.For those interested in purchasing high-quality aluminum alloy die casting molds for sale, ensure that you choose a supplier who understands the intricacies of temperature control and provides comprehensive solutions for maintaining optimal mold conditions.

die casting mould manufacturer aluminum alloy die casting mold for sale die casting mould supplier