Why Customization Matters in Precision Mold Components?

In the world of manufacturing, precision is key, especially when it comes to producing intricate parts that demand high accuracy. Precision mold components are essential for creating these detailed parts, but standard, off-the-shelf components often fall short in meeting specific requirements. This is where customization comes into play, offering tailored solutions that meet the unique needs of various industries. Let's explore why customization matters in precision mold components and how it can benefit your manufacturing process.

1. Meeting Specific Requirements

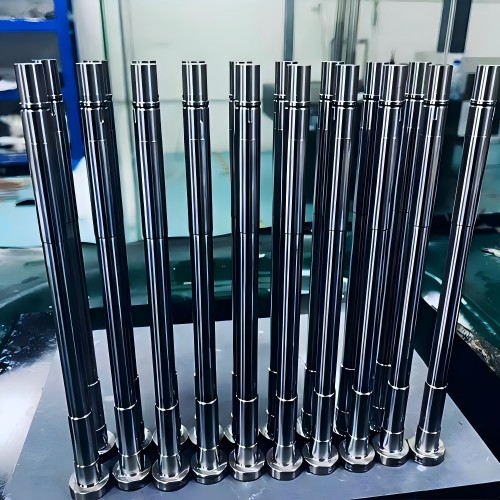

Every industry has its own set of requirements, and a one-size-fits-all approach rarely works when it comes to precision mold components. Customization allows manufacturers to design components that precisely match the specifications of their projects. Whether it's the size, shape, material, or functionality, customized precision mold components ensure that every aspect of the part aligns with the intended use. A reliable precision mold components manufacturer like Hairong offers the flexibility to create components that are perfectly suited to your needs.

2. Enhancing Efficiency and Productivity

Using customized precision mold components can significantly enhance efficiency in the manufacturing process. When components are specifically designed to fit the mold and application, they perform better, reduce waste, and minimize the need for adjustments or rework. Precision mold components customize services ensure that each part functions optimally within the production line, leading to faster turnaround times and higher productivity. This level of efficiency is especially crucial in industries where time and precision are of the essence.

3. Improving Product Quality

Quality is non-negotiable in manufacturing, and customized precision mold components play a vital role in achieving superior product quality. By tailoring components to meet exact specifications, manufacturers can avoid common issues such as misalignment, poor fit, or premature wear. Hairong precision mold components, for instance, are known for their high-quality standards and attention to detail, ensuring that each component contributes to the overall quality of the final product.

4. Addressing Unique Challenges

Every project comes with its own set of challenges, and standard components may not always be able to address these effectively. Customization allows for the creation of precision mold components that can overcome specific hurdles, such as working with challenging materials, maintaining tight tolerances, or withstanding extreme conditions. A precision mold components service that offers customization can help you navigate these challenges by providing solutions that are tailor-made for your application.

5. Staying Competitive in the Market

In today’s competitive market, having the ability to offer unique and high-quality products can set you apart from the competition. Customizing precision mold components not only ensures that your products meet the highest standards but also allows you to innovate and create designs that are difficult for competitors to replicate. Hairong precision mold components manufacturer provides the expertise and capabilities to deliver customized components that give your products a competitive edge.

Customization in precision mold components is not just a luxury; it’s a necessity for manufacturers aiming to produce high-quality, efficient, and reliable products. By partnering with a trusted precision mold components manufacturer like Hairong, you can take advantage of precision mold components customize services to meet your specific needs and achieve better results in your production process. Whether you’re facing unique challenges or simply want to enhance the quality and efficiency of your operations, customized precision mold components are the key to success.

precision mold components manufacturer precision mold components service precision mold components customize Hairong precision mold components