What Factors Should You Consider When Ordering Custom Mould Parts?

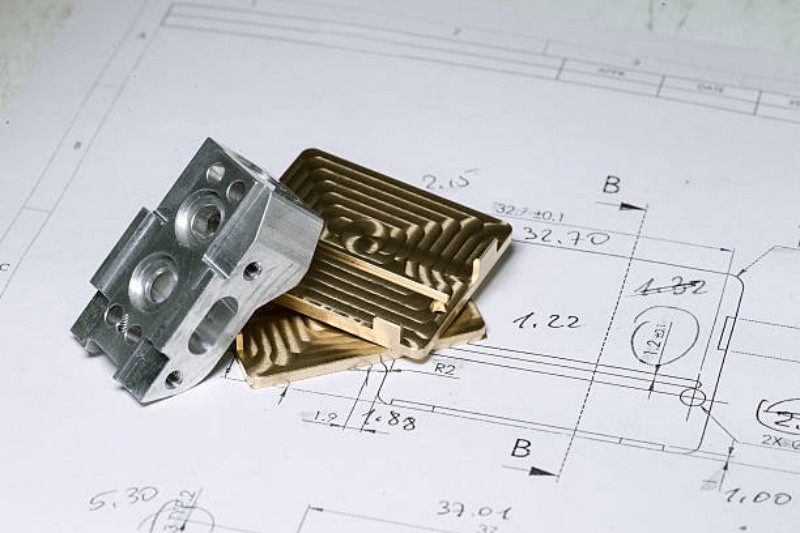

In modern manufacturing, custom mould parts are a cornerstone of precision and efficiency. From automotive components to electronics and industrial machinery, the right mould parts ensure superior product quality, reduce defects, and optimize production processes. Selecting the appropriate precision mould parts requires careful planning and an understanding of key factors that influence performance, durability, and cost.

1. Material Selection Matters

The choice of material directly impacts the longevity and reliability of high-precision mold parts. Common materials include stainless steel, aluminum alloys, and hardened tool steel. For applications that demand high wear resistance, corrosion resistance, or thermal stability, selecting the right material ensures that your precision mold components maintain dimensional accuracy under repeated use. Additionally, eco-conscious manufacturers may seek suppliers offering sustainable or recyclable materials for industrial mould parts.

2. Manufacturing Accuracy and Tolerances

Accuracy is critical for custom mould parts. Even minor deviations can lead to misalignment, product defects, or inefficient production. When sourcing precision mould parts, evaluate the supplier’s tolerance capabilities and quality control methods. Advanced manufacturing processes such as CNC machining, EDM, and laser measurement can help guarantee that your high-precision mold parts meet exact specifications, which is especially important in industries where consistency is non-negotiable.

3. Supplier Expertise and Capabilities

Not all suppliers can deliver industrial mould parts that meet stringent quality and precision standards. Experienced manufacturers provide insights on part design, material selection, and process optimization. When ordering custom mould parts, choose suppliers with proven track records, certifications, and the ability to handle complex geometries. A reliable supplier not only manufactures components but also advises on improving durability, reducing cycle times, and minimizing waste.

4. Customization Requirements

Every project has unique specifications. Clearly defining your requirements—such as surface finish, tolerances, and functional features—is essential when ordering custom mould parts. Some projects may demand high-precision mold parts with tolerances within 0.01 mm, while others may prioritize durability under high temperature or chemical exposure. Detailed specifications ensure the manufacturer produces precision mould parts that fit seamlessly into your production line.

5. Production Volume and Lead Time

The quantity of parts and project timeline influence your choice of supplier and production method. High-volume manufacturing often benefits from injection moulding or automated CNC processes, while low-volume or prototype orders may require 3D printing or manual machining. Understanding production volume and lead time ensures your custom mould parts and industrial mould parts are delivered efficiently without compromising precision.

6. Cost Considerations

While quality is paramount, cost is always a factor in B2B manufacturing decisions. The price of precision mold components depends on material, complexity, precision, and order quantity. Balancing upfront costs with long-term benefits—such as reduced maintenance, fewer defects, and longer lifespan—ensures that investing in high-precision mold parts is cost-effective over the production cycle.

7. Quality Control and Testing

Rigorous quality control is a hallmark of reliable custom mould parts suppliers. Dimensional checks, material testing, and surface inspections verify that each component meets specifications. Some suppliers offer trial runs or pre-shipment samples, giving buyers confidence in the consistency and reliability of precision mould parts and industrial mould parts before committing to large orders.

8. Communication and Technical Support

Effective communication is essential when sourcing custom mould parts. Providing detailed CAD drawings, technical specifications, and functional requirements minimizes misunderstandings. A responsive supplier can offer technical support, suggest improvements, and troubleshoot issues, ensuring that precision mold components integrate seamlessly into your production process.

9. Industry Standards and Certifications

Compliance with industry standards ensures that high-precision mold parts meet safety, quality, and performance requirements. Look for ISO certifications, quality management systems, and adherence to relevant manufacturing standards. This not only guarantees reliable industrial mould parts but also enhances trust when working with international partners.

Ordering custom mould parts is a critical step in modern manufacturing. By carefully considering material selection, manufacturing accuracy, supplier expertise, customization needs, production volume, cost, quality control, communication, and industry certifications, you can secure precision mould parts, precision mold components, high-precision mold parts, and industrial mould parts that elevate your production quality.

Selecting the right supplier and clearly defining requirements ensures reliable components, optimized production, and long-term cost efficiency. Investing in high-quality custom mould parts is not just a procurement decision—it is a strategic step toward superior product quality, consistent output, and competitive advantage.

custom mould parts precision mould parts precision mold components high-precision mold parts industrial mould parts