What Makes High-Quality Plastic Mould Parts Essential for Precision Manufacturing?

A cornerstone of achieving these standards lies in the quality of plastic mould parts. Whether used in the automotive, electronics, medical, or consumer goods industries, these components are vital to ensuring product performance, structural integrity, and cost-effective production.

Why Plastic Mould Parts Are Indispensable

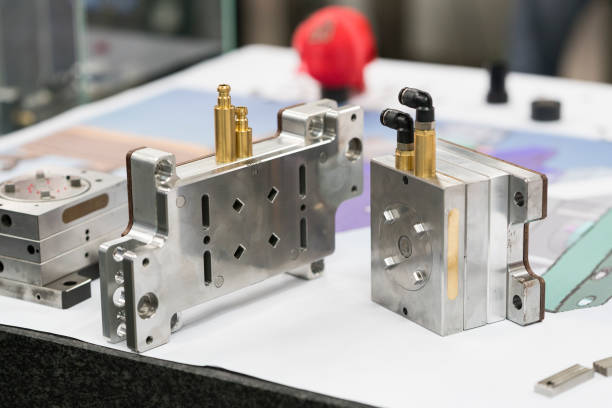

Plastic mould components are the foundation of any injection moulding system. Substandard mould parts can lead to a host of manufacturing issues, including dimensional deviations, surface imperfections, frequent maintenance, and increased rejection rates. For manufacturers committed to delivering high-quality products, investing in precision plastic mould parts is not optional—it’s a necessity.

Key Features of High-Quality Plastic Mould Components

What sets premium plastic mould parts apart? Several critical characteristics determine their performance and value:

Superior Material Selection: The use of high-grade tool steels and corrosion-resistant alloys enhances strength and longevity.

Ultra-Precision Machining: Tolerances measured in microns ensure consistent part dimensions and eliminate variation.

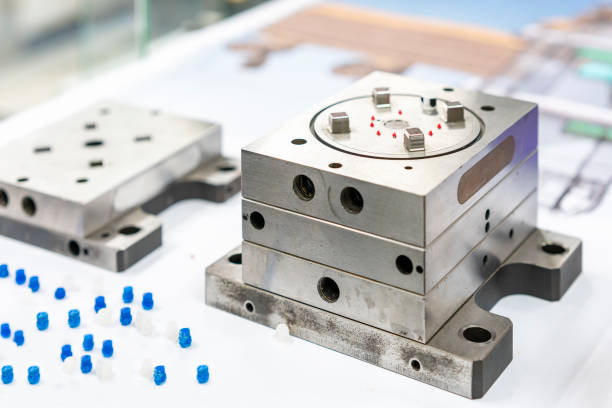

Production Consistency: Quality mould parts deliver repeatable performance across thousands—or even millions—of cycles.

Customization Capability: For complex projects, custom plastic molding parts are essential to meet exact design specifications and functional requirements.

Advantages of Partnering with a Professional Plastic Mould Part Manufacturer

Collaborating with an experienced plastic mould part manufacturer offers more than just parts—it delivers strategic advantages:

Reduced Lead Times: Streamlined processes and optimized workflows accelerate time to market.

Stringent Quality Control: Advanced inspection systems ensure every part meets or exceeds tolerance standards.

Engineering Expertise: Technical teams assist with mould design optimization, reducing errors and maximizing efficiency.

Complex Project Capability: Expertise in multi-cavity, insert, and overmoulding techniques enables the handling of highly complex components.

Industry Applications of Plastic Injection Mould Parts

Injection moulded plastic components are widely used in:

Automotive: Dashboard assemblies, sensor housings, and electrical connectors

Medical Devices: Syringes, surgical tools, and diagnostic equipment casings

Consumer Electronics: Battery holders, enclosures, and switch covers

Home Appliances: Control interfaces, internal supports, and exterior panels

Why Choose Hairong?

At [Your Brand Name], we are specialists in high-precision plastic mould parts tailored for demanding industrial applications. As a trusted plastic mould part manufacturer, we offer:

ISO-Certified Manufacturing Facilities

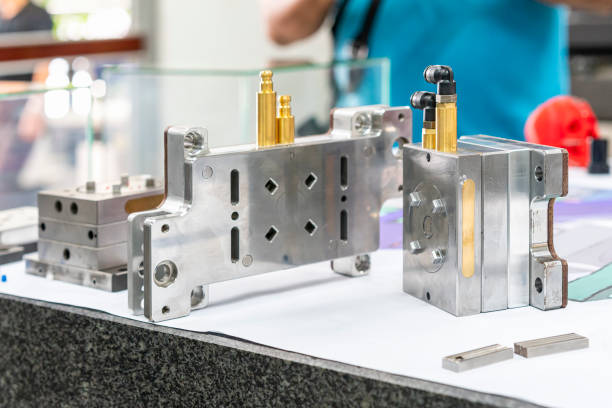

State-of-the-Art CNC and EDM Machining

Comprehensive Quality Control from Prototype to Production

Custom OEM/ODM Services for unique and complex requirements

In the world of precision manufacturing, cutting corners on mould component quality can have costly consequences. Partnering with a reliable supplier of high-performance plastic mould parts ensures product consistency, efficiency, and long-term cost savings.

plastic mould part manufacturer precision plastic mould components custom plastic molding parts