Choosing the Best Precision Mold Components Supplier: 5 Key Factors to Consider

Selecting the right precision mold components supplier is critical to maintaining consistent product quality, efficiency, and competitive edge. Whether you’re in automotive, medical, or consumer electronics, your tools are only as good as the components inside them. A high-quality supplier doesn’t just deliver parts—they deliver precision, reliability, and long-term value. So, what exactly should you look for when choosing the best partner? Here are five key factors worth serious consideration.

1. Expertise in High Precision Mold Components Manufacturing

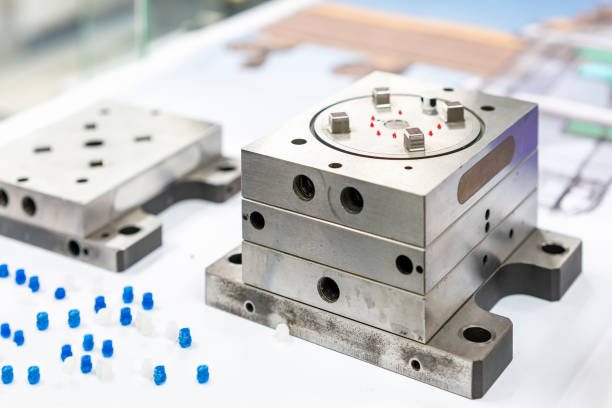

Precision in molding isn't optional—it's essential. The ideal custom made precision mold parts supplier should demonstrate in-depth technical expertise and years of hands-on experience producing high precision mold components with tolerances down to microns. Whether you're sourcing ejector pins, core inserts, or guide pillars, the supplier must offer dimensional consistency, perfect surface finishes, and flawless integration into complex molds. Look for evidence of specialization in precision cavity components, particularly for industries that require micro-level accuracy such as medical device molding and electronics casings.

2. Customization Capabilities and Engineering Support

No two projects are exactly alike. Your supplier should be equipped to provide custom made precision mold parts tailored to your mold design, cycle requirements, and material specifications. More importantly, they should offer co-engineering support—assisting with DFM (Design for Manufacturability), recommending optimal alloys, and ensuring long-term performance under high-pressure, high-temperature environments. Suppliers with in-house R&D teams and rapid prototyping abilities can turn your requirements into production-ready parts faster and with fewer design iterations.

3. Quality Assurance and Material Traceability

Precision starts with quality materials and ends with rigorous inspection. Ask your potential supplier what certifications they hold—ISO 9001 is a must, while ISO 13485 or IATF 16949 may be required depending on your industry. A reputable precision mold components supplier will perform 100% dimensional checks using CMM, vision systems, and surface roughness testing. They should also offer full material traceability for critical components, including certificates for heat treatment and surface coating.

4. Production Capacity and On-Time Delivery

A high-performing supplier must match your demand in terms of both quantity and timeline. Whether you need 50 cavity inserts for a prototype or 10,000 hardened pins for mass production, the supplier’s production line should be scalable. Additionally, ask about lead times, logistics support, and their history of on-time delivery. Suppliers with global clients often maintain international shipping lines and stock-ready inventory, ensuring you never miss a project deadline.

5. Cost-Effectiveness Without Compromising Quality

While price shouldn't be the sole deciding factor, it’s crucial that your supplier provides value for money. The best custom made precision mold parts supplier will optimize costs through process automation, lean production, and long-term material sourcing partnerships—without compromising performance.

Request a breakdown of pricing structures, mold life estimates, and maintenance recommendations. This ensures not only competitive quotes, but also transparency and trust over the lifecycle of your partnership

Final Thoughts:

Finding the right precision mold components supplier can transform your production workflow—from reduced tooling errors and downtime to increased mold longevity and part consistency. Whether you're sourcing high precision mold components for complex medical devices or durable precision cavity components for large-scale automotive tooling, choosing a supplier that meets all five criteria above will ensure you stay ahead in your industry. Looking for a trusted custom made precision mold parts supplier with deep manufacturing experience and global delivery capability? Contact us today to explore precision solutions tailored to your mold performance goals.

custom made precision mold parts supplier high precision mold components precision cavity components