Can High Precision Components Save You Money in the Long Run?

When it comes to manufacturing and product development, the use of high precision components is often seen as an investment that may require a higher upfront cost. However, this investment can offer significant long-term savings and benefits that make it well worth considering. In this article, we will explore how precision parts manufacturing and working with a reputable precision mould part manufacturer can save you money in the long run, while improving the overall quality and efficiency of your products.

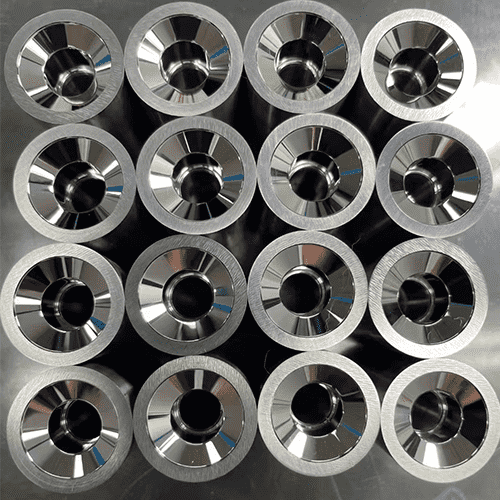

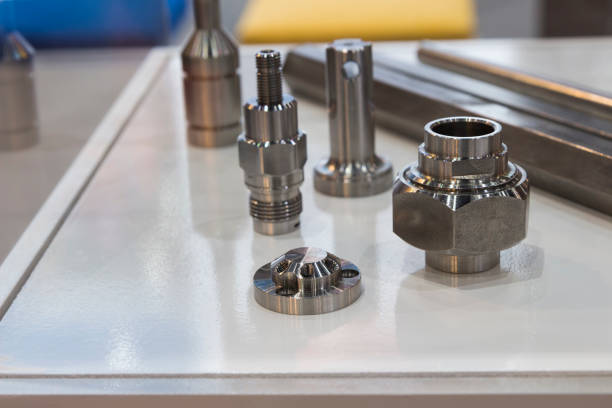

What Are High Precision Components?

High precision components refer to parts that are manufactured with extremely tight tolerances and accuracy. These components are designed to meet exact specifications, ensuring that they fit perfectly into the larger assembly or system. The precision involved in their creation ensures that they perform optimally, without causing inefficiencies or breakdowns. Precision parts manufacturing often involves advanced technologies such as CNC machining, injection molding, or additive manufacturing to achieve these high standards.

How Do High Precision Components Improve Product Quality?

One of the key ways high precision components save you money over time is by significantly improving product quality. When parts are manufactured to exact specifications, there is a lower likelihood of defects, malfunctions, or the need for rework. High precision ensures that the parts fit perfectly together, which leads to fewer issues with assembly or performance down the line. As a result, products are more reliable and durable, reducing the frequency of repairs or replacements. Moreover, precision mould part manufacturers use the latest technology to create components that consistently meet high standards. This precision translates to better functionality and a more efficient product, which can ultimately lead to higher customer satisfaction and fewer returns, further saving costs in the long term.

Reducing Waste and Material Costs

In traditional manufacturing processes, a significant amount of waste can occur due to inaccuracies or poor tolerances. When parts are not precisely manufactured, the excess material used to make up for errors adds to costs. High precision components, however, minimize this issue by ensuring that every piece is made to exact specifications, reducing waste during production. By working with a reliable precision parts manufacturing company, manufacturers can achieve optimal material usage, reducing unnecessary waste. This contributes to overall cost savings, especially when large volumes of components are produced. The more accurate the components, the fewer resources are wasted in production, leading to better cost efficiency.

Enhancing Efficiency and Reducing Downtime

High precision parts contribute to operational efficiency by ensuring that the components work seamlessly together, reducing the likelihood of malfunctions or downtime. Precision parts manufacturing aims to create components that are easy to assemble, durable, and reliable over time. This efficiency reduces the time spent fixing or replacing faulty parts, which can be costly in terms of labor and productivity. For example, in industries like automotive manufacturing, aerospace, or electronics, downtime due to faulty parts can be extremely costly. When high precision components are used, the risk of failure is minimized, leading to fewer production interruptions and reduced repair costs. This increased operational efficiency can result in significant long-term savings, making high precision components a smart choice for businesses looking to maximize their bottom line.

Long-Term Durability and Reliability

One of the greatest advantages of high precision components is their longevity. Because these components are built to exacting standards, they tend to last longer and perform better than standard parts. The durability of these components translates to reduced maintenance and fewer replacements over the life of the product. For instance, precision mould part manufacturers create components with high-strength materials and excellent finishing, which can withstand more wear and tear than their counterparts. The superior durability of high precision parts means that your products will require less frequent repairs and will continue to perform optimally for a longer period of time, saving both time and money.

Why Choose a Precision Mould Part Manufacturer?

When sourcing high precision components, it's crucial to work with an experienced precision mould part manufacturer that can deliver high-quality parts consistently. A reputable manufacturer has the expertise, technology, and quality control systems in place to ensure that the components are manufactured with the utmost precision. By selecting a trusted manufacturer, businesses can ensure that they are getting the best possible parts for their products. This partnership helps to reduce errors, delays, and defects in production, leading to fewer costly setbacks. Choosing the right manufacturer also means that your components will be made using advanced technologies and high-quality materials, further enhancing their performance and lifespan.

The Bottom Line: How High Precision Components Save You Money

While the initial cost of high precision components may seem higher than standard parts, the long-term benefits are clear. From reducing waste and material costs to improving product quality and operational efficiency, these components offer significant savings over time. Their durability and reliability also lead to fewer repairs and replacements, minimizing long-term maintenance costs. Ultimately, precision parts manufacturing and partnering with a skilled precision mould part manufacturer can provide your business with a competitive advantage by ensuring that your products are of the highest quality, while also saving you money on repairs, replacements, and operational downtime. Investing in high precision components is a smart financial decision that pays off in the long run. By making the switch to high precision, you not only improve the quality of your products but also contribute to better overall cost efficiency in your manufacturing process. The savings, both direct and indirect, are substantial and will help you achieve long-term success.

high precision components precision parts manufacturing precision mould part manufacturer