Custom Precision Mould Manufacturing: Enhancing Quality and Efficiency

Custom precision mould manufacturing plays a vital role in producing high-quality, durable, and intricately designed components across various industries. Whether for automotive, electronics, medical, or consumer goods, precision moulds ensure consistency, efficiency, and superior product performance. This article explores the importance of custom precision mould manufacturing, its benefits, and why working with an experienced precision mould part manufacturer is essential for achieving the best results.

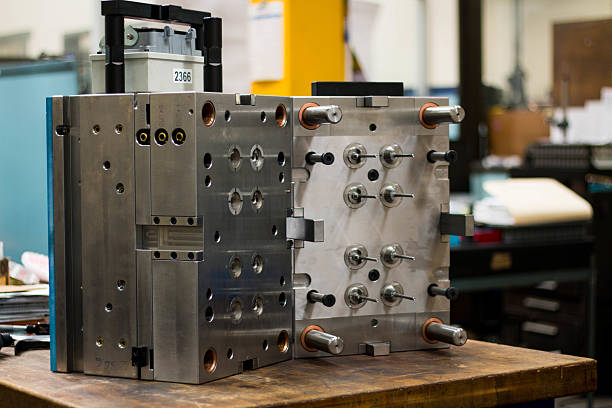

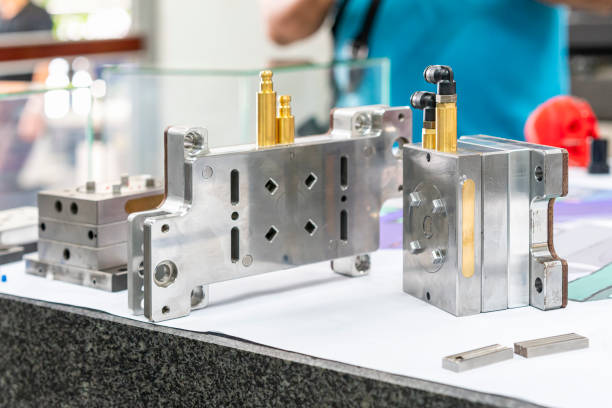

What Is Custom Precision Mould Manufacturing?

Custom precision mould manufacturing is the process of designing and producing moulds tailored to specific product requirements. Unlike standard moulds, which follow general specifications, custom precision moulds are engineered with extreme accuracy to meet exact tolerances. Advanced precision moulding services ensure that each mould delivers consistent results, minimizing errors and maximizing production efficiency.

Key Benefits of Custom Precision Mould Manufacturing

1. Superior Accuracy and Consistency

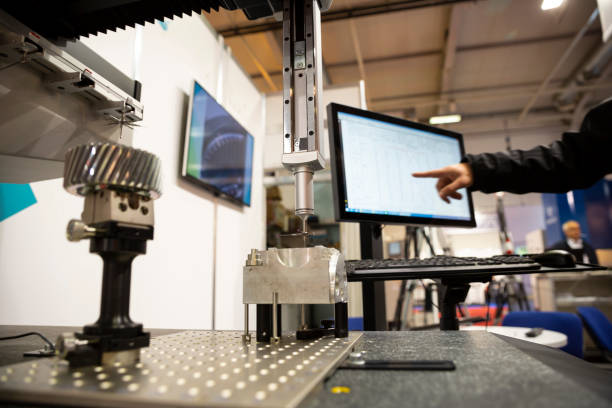

Precision is the foundation of high-quality moulding. With custom mould parts, manufacturers can achieve exact dimensions, ensuring that every component fits perfectly. This is especially critical in industries where even the smallest deviation can affect product functionality, such as medical devices or aerospace components.

2. Enhanced Product Quality

A well-designed custom precision mould ensures that the final product is free from defects such as warping, shrinkage, or surface imperfections. High-precision moulding techniques result in smooth finishes, structural integrity, and excellent repeatability, allowing businesses to maintain high product standards.

3. Optimized Material Selection

Custom mould manufacturing allows manufacturers to choose the most suitable materials for their specific applications. Whether using high-performance plastics, metals, or composite materials, selecting the right material enhances durability, resistance to wear, and overall product performance.

4. Cost-Effective Production

Investing in custom precision mould manufacturing reduces waste, minimizes rework, and lowers overall production costs. With precision-moulded parts, manufacturers can streamline assembly processes, reduce material waste, and increase operational efficiency.

5. Faster Production Cycles

A well-designed precision mould ensures smooth and efficient production, reducing lead times and increasing output. High-speed precision moulding services allow for rapid, large-scale production without compromising quality.

Applications of Custom Precision Mould Manufacturing

1. Automotive Industry

Precision moulds are essential for manufacturing complex automotive parts, including engine components, interior fittings, and structural elements. Custom moulding ensures these parts meet strict safety and performance standards.

2. Medical Device Manufacturing

In the medical field, precision is critical. Custom moulds produce intricate medical components such as surgical tools, implants, and diagnostic devices, ensuring compliance with stringent regulations.

3. Electronics and Consumer Goods

From smartphone casings to circuit board components, custom mould parts provide the necessary precision for manufacturing high-performance electronic devices and durable consumer products.

4. Aerospace and Industrial Applications

Aerospace and industrial sectors rely on precision moulding to produce lightweight yet strong components, helping improve performance and efficiency in critical applications.

Choosing the Right Precision Mould Part Manufacturer

To achieve the best results, it’s crucial to partner with a reliable mould part supplier that specializes in custom precision mould manufacturing. A reputable supplier will offer:

Advanced precision moulding services using CNC machining, EDM, and injection moulding technology.

Expertise in material selection and mould design to meet industry-specific needs.

Strict quality control measures to ensure each mould meets exact specifications.

Custom precision mould manufacturing is a game-changer for industries that demand high accuracy, superior quality, and efficient production processes. By working with an experienced precision mould part manufacturer, businesses can benefit from custom mould parts that enhance product performance, reduce costs, and improve overall manufacturing efficiency. Whether for automotive, medical, electronics, or industrial applications, investing in precision moulding services ensures long-term success in an increasingly competitive market.