How Do Custom Mould Parts Enhance Product Quality?

One of the key factors that significantly enhance the overall quality of a product is the precision and design of the mould parts used in its creation. Whether you're producing automotive components, electronics, or medical devices, custom mould parts are essential in achieving superior product quality. In this article, we’ll explore how custom mould parts, along with the services of a precision mould part manufacturer, contribute to improved product outcomes.

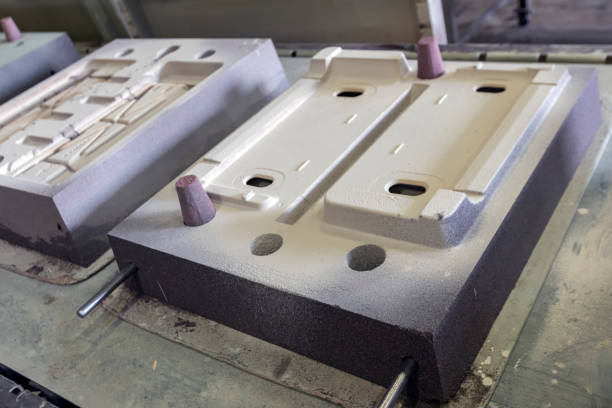

The Role of Custom Mould Parts in Quality Control

Custom mould parts are tailored to meet the specific needs of a particular product. By choosing custom solutions, manufacturers ensure that every component fits precisely within the product's design specifications. Unlike standard mould parts, which may not perfectly align with the unique requirements of a project, custom mould parts allow for more flexibility and adaptability, significantly reducing the chances of defects or production delays. The precision in these parts is achieved through advanced technologies such as CNC machining and 3D printing, ensuring that the mould parts meet tight tolerances and the highest quality standards.

Advantages of Custom Mould Parts for High-Precision Products

Working with a precision mould part manufacturer offers many advantages when producing high-quality, durable products. Here are a few ways custom mould parts improve product quality:

1. Exact Fit and Functionality:

Custom mould parts are designed to meet the precise dimensions required for a product, reducing the risk of defects caused by poor fitment. This is especially important in industries like electronics and medical devices, where even the smallest flaw can compromise performance or safety.

2. Optimized Material Use:

By designing custom mould parts specifically for a project, manufacturers can select the most suitable materials that align with the product’s intended use, resulting in enhanced durability and functionality. The right material choices, paired with precision moulding, ensure that the final product performs well under its expected conditions.

3. Reduced Waste and Cost:

Custom mould parts eliminate the need for costly rework and waste by providing a precise and reliable design from the outset. This reduction in errors can translate into lower production costs and fewer defective products, further improving the overall product quality.

4. Improved Aesthetics:

Precision moulding services, offered by experienced mould part suppliers, can produce custom parts that not only function effectively but also look great. This is particularly important for consumer-facing products, where aesthetics can play a significant role in the product’s market appeal.

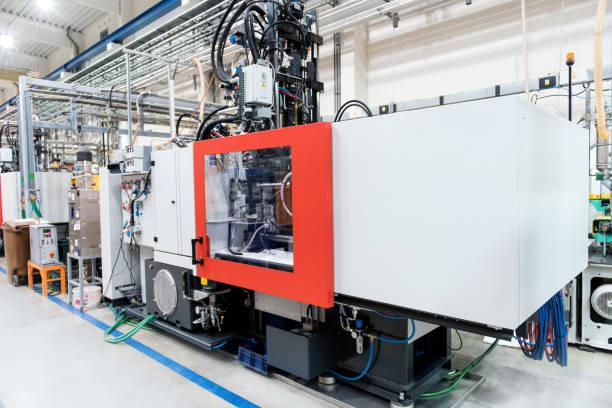

The Precision Moulding Process

Precision moulding is an advanced manufacturing technique used by precision mould part manufacturers to create custom parts with high accuracy. This process involves intricate control over the shaping of materials such as metals, plastics, and composites to meet tight tolerances and design specifications. By employing this method, manufacturers can produce mould parts that perfectly match the desired end-product design, ensuring optimal quality and performance.

Working with a Reliable Mould Part Supplier

Partnering with a reputable mould part supplier is critical to ensuring that your custom mould parts meet the highest standards. The supplier should offer precision moulding services backed by years of experience and expertise. Look for a supplier who provides comprehensive services, from design and prototyping to production and quality control, ensuring a seamless process that maintains the integrity of the custom mould parts throughout manufacturing.

Custom mould parts are integral to enhancing product quality in manufacturing. With the help of a precision mould part manufacturer, businesses can create high-performance products that meet exact specifications and function flawlessly. The use of precision moulding services ensures that every part is crafted with attention to detail, reducing the risk of defects and increasing overall product reliability. By choosing a trusted mould part supplier, manufacturers can ensure that their custom mould parts contribute to higher-quality, more durable, and aesthetically pleasing products, setting their business up for long-term success. By incorporating these practices and working with the right experts, you’ll see firsthand how custom mould parts can elevate your product quality to the next level.

precision mould part manufacturer custom mould parts precision moulding services mould part supplier