The Hidden Power of Precision Mold Components in Manufacturing

When it comes to manufacturing, precision is not just a preference—it’s a necessity. While much attention is given to machinery and materials, one of the most critical yet overlooked factors is the role of precision mold components. These small but powerful parts serve as the backbone of high-quality production, ensuring that every molded product meets strict industry standards.

What Makes Precision Mold Components So Important?

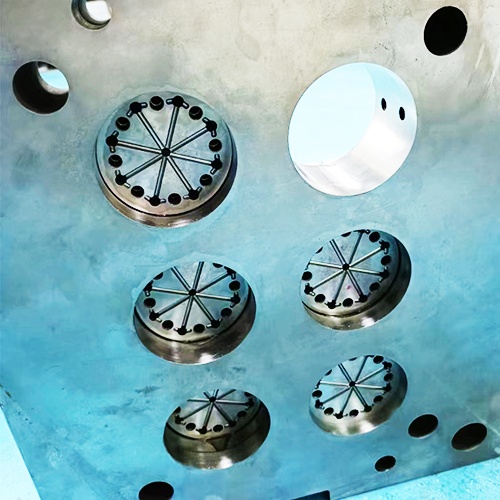

Precision mold components are designed to fit within molding systems with extreme accuracy, ensuring flawless product replication. These components, including ejector pins, core pins, lifters, and bushings, play a vital role in shaping, forming, and releasing molded parts. Without high-precision components, manufacturers risk defects, inefficiencies, and increased production costs.

Key Advantages of Precision Mold Components

Unmatched Accuracy – Precision mold components guarantee tight tolerances, eliminating inconsistencies in the final product.

Efficiency Boost – By ensuring seamless operations, these components reduce downtime and increase production speed.

Durability & Longevity – Made from hardened steel and carbide, they withstand extreme conditions, extending the life of molds.

Cost Savings – Fewer defects mean less waste, lower maintenance costs, and higher profitability.

Versatility Across Industries – Used in automotive, medical, electronics, and consumer goods manufacturing, these components adapt to diverse applications.

Industries That Rely on Precision Mold Components

Automotive Manufacturing – Ensuring the production of highly durable engine parts and interior components.

Electronics Industry – Facilitating the creation of small, complex parts for devices like smartphones and computers.

Medical Equipment Production – Guaranteeing sterile and high-precision surgical tools and healthcare components.

Consumer Goods Manufacturing – Enabling mass production of everyday plastic and metal products.

Choosing the Right Precision Mold Components

For maximum efficiency, manufacturers should invest in custom mold parts made with high-grade materials and produced with advanced machining technologies. Selecting the right supplier ensures durability, precision, and seamless integration into existing production lines.

Final Thoughts:

Precision mold components may be small, but their impact on manufacturing is enormous. By investing in high-quality mold parts, businesses can improve efficiency, reduce costs, and maintain consistent product quality. These components are the unsung heroes of modern manufacturing, driving innovation and excellence behind the scenes.

precision mold components custom mold parts high-precision molding accessories