Custom Plastic Injection Molding: A Reliable Solution for Precision Manufacturing

Custom plastic injection molding is one of the most efficient and cost-effective manufacturing processes for producing high-quality plastic components. Industries such as automotive, medical, electronics, and consumer goods rely on this method to create durable and precise plastic parts. As a leading provider of custom plastic injection molding services, we specialize in delivering tailored solutions that meet the specific requirements of businesses worldwide.

What Is Custom Plastic Injection Molding?

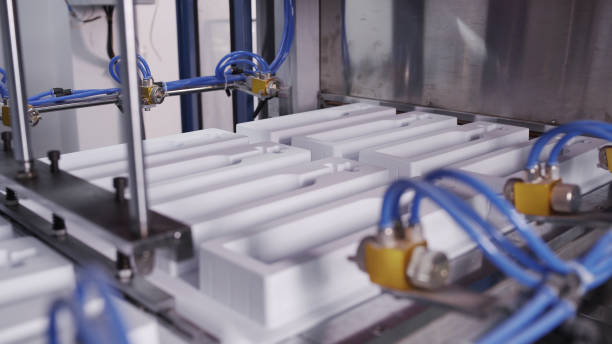

Custom plastic injection molding is a process that involves injecting molten plastic into a pre-designed mold to form complex shapes with high accuracy. This technique is widely used due to its ability to produce large quantities of parts with consistent quality, tight tolerances, and excellent durability. The process includes several key stages:

- Mold Design and Fabrication – Creating a precise mold based on the client's design specifications.

- Material Selection – Choosing the appropriate plastic material to ensure strength, flexibility, and resistance properties.

- Injection Molding Process – Injecting the molten plastic into the mold cavity at high pressure.

- Cooling and Ejection – Allowing the plastic to cool and solidify before ejecting the final product.

- Quality Inspection – Ensuring each part meets required standards before shipment.

Benefits of Custom Plastic Injection Molding

Choosing custom plastic injection molding offers several advantages over traditional manufacturing methods:

- High Efficiency and Mass Production – Enables the rapid production of thousands to millions of identical parts with minimal waste.

- Precision and Consistency – Ensures uniformity across all parts, maintaining strict dimensional tolerances.

- Cost-Effective – Once the mold is created, large-scale production significantly reduces per-unit costs.

- Wide Material Selection – Compatible with a variety of plastic materials, including ABS, polycarbonate, nylon, and polypropylene.

- Complex Design Capabilities – Ideal for producing intricate shapes and detailed components that are difficult to manufacture with other methods.

Applications of Custom Plastic Injection Molding

Custom plastic injection molding is widely used across multiple industries due to its versatility and efficiency:

- Automotive – Producing dashboard components, bumpers, and interior fittings.

- Medical Devices – Manufacturing precise medical tools, syringes, and casings for healthcare applications.

- Electronics – Creating durable plastic housings for smartphones, laptops, and other electronic devices.

- Consumer Goods – Producing plastic parts for appliances, packaging, and household products.

- Industrial Components – Manufacturing strong and lightweight parts for machinery and equipment.

Choosing the Right Custom Plastic Injection Molding Manufacturer

Selecting the best custom plastic injection molding manufacturer is essential for achieving high-quality results. Here are key factors to consider:

- Experience and Expertise – Choose a company with proven expertise in designing and manufacturing complex plastic parts.

- Advanced Technology and Equipment – Ensure the manufacturer uses modern injection molding machines and precision tooling.

- Material Selection and Customization – Look for a provider that offers a variety of materials and customization options.

- Quality Control and Certifications – Verify compliance with industry standards such as ISO 9001 for quality assurance.

- Production Capacity and Lead Time – Work with a manufacturer that can handle large-scale orders efficiently and deliver on time.

Why Choose Our Custom Plastic Injection Molding Services?

As a leading provider of custom plastic injection molding solutions, we offer:

- Comprehensive design support to optimize your product for manufacturability.

- High-precision molds for consistent quality and performance.

- A wide range of materials, including thermoplastics and engineering-grade resins.

- Cost-effective production with fast turnaround times.

- Strict quality control to ensure every product meets industry standards.

Custom plastic injection molding is an essential manufacturing process for producing high-quality plastic components with precision and efficiency. Whether you need automotive, medical, electronics, or consumer goods solutions, partnering with a reliable injection molding manufacturer ensures your products meet the highest quality standards.

custom plastic injection molding custom plastic injection molding services plastic injection molding manufacturer custom injection molding