Precision Plastic Mold Accessories: Enhancing Manufacturing Efficiency and Quality

In modern manufacturing, precision plastic mold accessories play a crucial role in ensuring high-quality production, improved efficiency, and cost reduction. These components support mold performance, extend tool life, and contribute to the overall consistency of plastic molding processes. As the demand for precision engineering grows, industries such as automotive, medical, electronics, and consumer goods increasingly rely on high-performance mold accessories to meet their stringent requirements.

Key Features of Precision Plastic Mold Accessories

Precision plastic mold accessories are designed to enhance the accuracy and durability of injection molding tools. High-quality mold components ensure consistent production by reducing defects, minimizing downtime, and optimizing cycle times. Key features include:

- High precision and tight tolerances – Ensures consistent and accurate plastic part production.

- Durable materials – Made from high-quality steels, alloys, and advanced polymers for extended mold life.

- Corrosion and wear resistance – Protects against heat, pressure, and prolonged usage in high-output environments.

- Customizable designs – Tailored mold accessories allow for optimized performance based on specific industry needs.

- Compatibility with various molding techniques – Supports injection molding, blow molding, and compression molding.

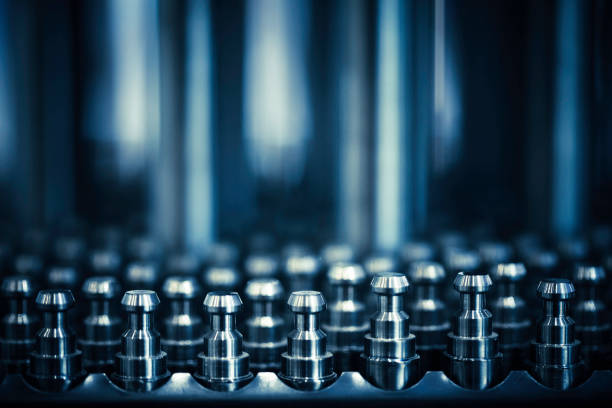

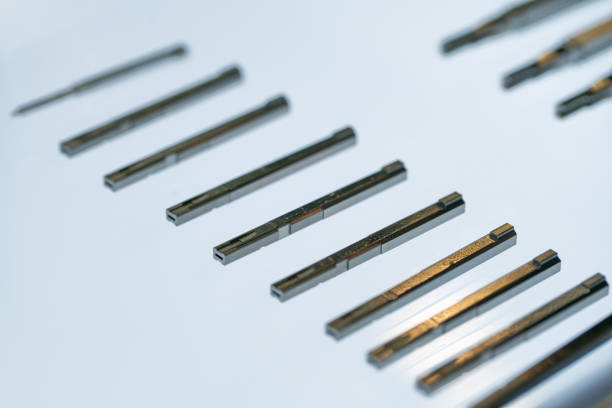

Types of Precision Plastic Mold Accessories

Manufacturers rely on a wide range of precision plastic mold accessories to improve the efficiency and longevity of their molds. Some of the essential components include:

- Mold Bases and Frames – Provide structural support for molds, ensuring stability and accuracy.

- Ejector Pins and Sleeves – Facilitate the smooth release of molded parts without causing damage.

- Guide Pins and Bushings – Ensure precise alignment between mold halves to prevent defects.

- Cooling System Components – Regulate mold temperature, preventing overheating and ensuring consistent part quality.

- Sprue Bushings and Nozzles – Guide molten plastic into the mold cavity efficiently.

- Core Pins and Inserts – Help shape intricate features and fine details in molded parts.

Applications of Precision Plastic Mold Accessories

Precision plastic mold accessories are widely used across multiple industries due to their ability to enhance product quality and manufacturing efficiency. Key application areas include:

- Automotive Industry – Used in the production of high-precision interior and exterior plastic components.

- Medical Devices – Essential for producing sterile and dimensionally accurate medical parts.

- Electronics & Telecommunications – Supports the manufacturing of durable and lightweight plastic enclosures and connectors.

- Consumer Goods – Helps create high-quality plastic packaging, containers, and household products.

How to Choose the Right Precision Plastic Mold Accessories Manufacturer

Selecting a reliable manufacturer for precision plastic mold accessories is essential to achieving optimal production efficiency and cost savings. Consider the following factors:

- Experience and Expertise – Choose manufacturers with a proven track record in precision mold components.

- Material Quality and Durability – Ensure they use high-grade materials resistant to wear and corrosion.

- Customization Options – Look for suppliers that offer tailored mold accessories to match specific requirements.

- Quality Assurance and Standards Compliance – Verify certifications such as ISO 9001 and industry-specific standards.

- Supply Chain Reliability – Work with manufacturers that guarantee consistent product availability and timely delivery.

The Future of Precision Plastic Mold Accessories

As automation and advanced molding technologies continue to evolve, the demand for precision plastic mold accessories will keep growing. Innovations in mold materials, cooling systems, and digital mold monitoring will further enhance production efficiency, reduce waste, and improve sustainability.

Precision plastic mold accessories are essential for high-quality, efficient, and cost-effective plastic molding operations. Investing in premium mold components can significantly improve product consistency, extend mold life, and reduce production downtime. Whether in automotive, medical, or consumer goods manufacturing, high-precision mold accessories play a crucial role in maintaining industry standards and meeting growing market demands.

For high-quality mold accessories designed for durability and performance, choose a trusted supplier with expertise in precision engineering.

precision plastic mold accessories precision plastic mold parts custom plastic mold accessories plastic mold accessories manufacturer