Precision Mould Parts: 10 Key Benefits and Essential Information

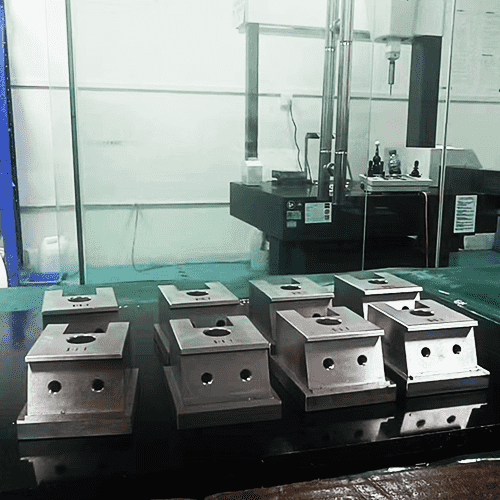

The manufacturing process begins with careful planning and design. Engineers use advanced CAD (computer-aided design) software to develop mould designs that meet the specific needs of the product. The design phase is crucial, as it influences the entire moulding process and determines how effectively the mould will produce the desired parts. Choosing the right material for precision mould parts is essential for achieving the desired strength, durability, and performance. Common materials include stainless steel for its strength, aluminum for its lightweight properties, and various plastics for cost-effectiveness. Mould fabrication is typically done through methods like CNC machining, electrical discharge machining (EDM), and injection moulding. These methods allow for high-precision moulds that can produce complex shapes with minimal error.

Key Benefits of Precision Mould Parts

Improved Product Quality

One of the most significant advantages of using precision mould parts is the consistent and high-quality output. Because the moulding process is so precise, the resulting parts are accurate and free from defects. This consistency ensures that products meet the required standards for performance and safety.

Consistency and Precision

Precision in the moulding process means that each part produced is almost identical to the next. This consistency is crucial in industries like electronics and automotive, where even small discrepancies can lead to performance issues or product failure.

Cost-Effectiveness

Though the initial investment in precision mould parts may be higher, they offer significant long-term savings. With less waste material, fewer defects, and less need for post-production adjustments, the overall cost of manufacturing decreases over time.

Versatility Across Industries

Precision mould parts are used in a variety of industries due to their versatility. Whether in automotive manufacturing, consumer electronics, or medical devices, precision moulding enables the creation of highly specialized and intricate parts that improve product functionality.

How Precision Mould Parts Enhance Product Performance

Reducing Errors and Defects

By minimizing variation in each part, precision moulding reduces the risk of defects, ensuring that the final product performs as expected. This is particularly important in high-stakes sectors like healthcare, where malfunctioning products can lead to serious consequences.

The Role of Technology in Mould Part Manufacturing

Automation in Manufacturing

Automation has revolutionized the moulding industry. By using automated systems, manufacturers can produce moulds and parts with greater speed and accuracy, reducing human error and lowering production costs.

3D Printing and Moulding

The advent of 3D printing technology is changing the way precision mould parts are designed and produced. With 3D printing, manufacturers can rapidly prototype and produce parts with complex geometries, offering a new level of flexibility in product development.

Common Materials Used for Precision Mould Parts

Steel and Alloys

Steel and metal alloys are commonly used in precision moulding due to their durability and ability to withstand high pressure and temperature.

Plastics and Composites

For applications where lightweight or cost-effective solutions are needed, plastics and composites are used. These materials can be molded into complex shapes while maintaining strength and reducing production costs.

Challenges in Precision Mould Part Manufacturing

Tooling Issues

Over time, tooling can wear out, which can impact the precision of moulding. Regular maintenance and replacement of tools are necessary to maintain high-quality production.

Material Limitations

Each material used for moulding has its own set of limitations. Manufacturers must choose the right material based on the specific needs of the part, including factors like strength, temperature resistance, and weight.

Industries That Benefit from Precision Mould Parts

Automotive

Precision mould parts are crucial in automotive manufacturing, where components like engine parts, gears, and safety devices require exact dimensions and high durability.

Electronics

In electronics, moulded parts are often used for casings, connectors, and internal components. Precision ensures that each part fits together perfectly, allowing devices to function properly.

Medical Devices

In the medical field, precision mould parts are used to create components like surgical tools, implants, and diagnostic equipment, where accuracy is paramount.

The Future of Precision Mould Parts

Sustainable Manufacturing

As sustainability becomes more important, manufacturers are looking for ways to make the production of precision mould parts more eco-friendly. This includes using renewable materials and energy-efficient processes.

Smart Mould Parts

The integration of IoT and AI into precision mould parts is another exciting development. These “smart” parts can monitor their own performance and report back to manufacturers, enabling predictive maintenance and improving overall efficiency.