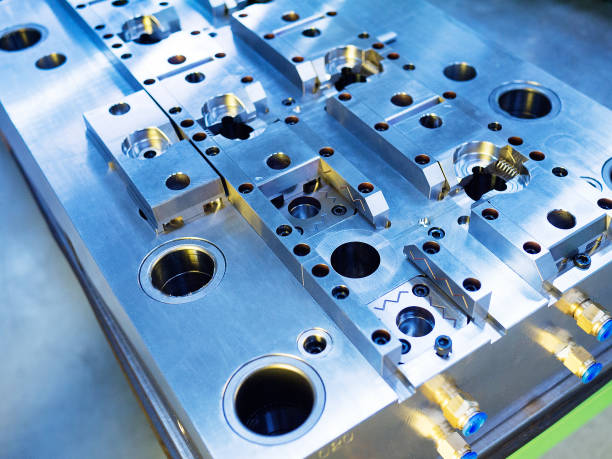

How Long Do Precision Injection Moulding Parts Last?

When investing in precision injection moulding parts, one of the most important considerations is their lifespan. Manufacturers and businesses across various industries rely on these parts for high-quality, durable products. Understanding the longevity of precision injection moulding parts can help businesses make informed decisions about material selection, production processes, and overall cost-effectiveness.In this article, we will discuss the factors that influence the lifespan of precision injection moulding parts and how to ensure these parts last as long as possible.

1. What Factors Influence the Lifespan of Precision Injection Moulding Parts?

The durability and longevity of precision injection moulding parts depend on several key factors, including the material used, the manufacturing process, and the conditions in which the parts are used. Let’s explore each of these factors in more detail:

Material Quality: The type of material used for precision injection moulding parts is perhaps the most significant factor in determining their lifespan. Common materials like ABS, polycarbonate, and polypropylene offer varying degrees of strength, heat resistance, and durability. For example:

ABS (Acrylonitrile Butadiene Styrene) is known for its high impact resistance and is often used in automotive and consumer electronics applications.

Polycarbonate is highly durable and resistant to impact, which makes it a popular choice for medical and safety-related parts.

Polypropylene is resistant to fatigue and wear, making it ideal for parts that will undergo repeated stress.

Choosing the right material for the specific application is crucial for maximizing the longevity of precision injection moulding parts.

Manufacturing Process: The process of creating precision injection moulding parts also plays a role in their lifespan. Proper tooling, mold design, and precise injection processes ensure the parts are produced to exact specifications, which improves durability. Any inconsistencies or errors during the manufacturing process can lead to weak points in the parts, reducing their overall lifespan.

Usage Conditions: The environment in which the precision injection moulding parts are used significantly impacts how long they will last. Exposure to harsh chemicals, extreme temperatures, moisture, or physical wear can all shorten the lifespan of the parts. In high-stress applications, such as automotive or industrial machinery, regular maintenance and inspections are critical to prevent premature failure.

2. How Long Do Precision Injection Moulding Parts Last in Different Applications?

The lifespan of precision injection moulding parts can vary depending on the specific application. Let’s take a look at how long these parts typically last in various industries:

Automotive Industry: In automotive applications, precision injection moulding parts are exposed to vibrations, temperature fluctuations, and mechanical stress. Parts such as dashboards, bumpers, and interior components made from high-quality materials like polycarbonate or ABS can last anywhere from 5 to 10 years, depending on usage and environmental conditions.

Consumer Electronics: Components such as casings for mobile phones, laptops, and home appliances are typically made from ABS or polycarbonate. These precision injection moulding parts can last several years, often around 3 to 5 years, depending on how often the products are used and how well they are maintained.

Medical Devices: Medical-grade precision injection moulding parts often have higher quality standards due to their critical function in healthcare. These parts, made from materials like medical-grade polypropylene or polycarbonate, are designed to withstand years of use. Medical parts may last 5 to 10 years or more, depending on the nature of the device and how it is used.

Industrial Machinery: Parts used in machinery and equipment are often exposed to high stresses, wear, and mechanical loads. Precision injection moulding parts made from durable materials like nylon or polypropylene can last for several years, but regular maintenance and inspection are necessary to extend their lifespan.

3. How to Extend the Lifespan of Precision Injection Moulding Parts?

Although the longevity of precision injection moulding parts is influenced by several factors, there are steps businesses can take to help extend the lifespan of these components:

Choose the Right Materials: Selecting the appropriate material for your specific application is essential. Ensure that the material has the right properties to withstand the environmental and operational conditions it will face. Work with a trusted precision injection moulding parts supplier to ensure you’re using the best material for the job.

Regular Maintenance: Performing routine inspections and maintenance on products using precision injection moulding parts is crucial. Regularly check for signs of wear, stress fractures, or fatigue that could indicate the parts are nearing the end of their life.

Proper Storage and Handling: Proper storage and handling can prevent damage to precision injection moulding parts before they even reach the production floor. Avoid exposure to extreme temperatures or chemicals that can cause premature degradation.

Opt for High-Quality Manufacturers: Working with a reputable custom mould parts supplier that uses precise manufacturing techniques and high-quality materials ensures that the parts are made to last. A quality supplier will also provide guidance on how to maintain parts for optimal performance over time.

The lifespan of precision injection moulding parts depends on several factors, including the material used, the manufacturing process, and the conditions in which the parts are used. By selecting high-quality materials, ensuring proper manufacturing processes, and following maintenance guidelines, you can significantly extend the life of these parts, ensuring long-term reliability and performance.

precision injection moulding parts precision injection moulding parts supplier