Precision Mould Parts: Crafting Excellence in Custom Moulding Solutions

Introduction to Precision Mould Parts

In today's competitive manufacturing landscape, achieving exceptional quality and durability is paramount. Industries ranging from automotive and electronics to medical devices and consumer goods rely heavily on precision mould parts to ensure product performance and longevity. Custom mould parts, high-precision mould components, and high-precision moulding services are at the heart of this innovation, enabling manufacturers to meet the stringent demands of their respective sectors. This article delves deep into the world of precision mould parts, exploring how custom mould solutions are shaping various industries and what businesses should consider when selecting high-precision moulding services for their production needs.

Understanding Custom Mould Parts

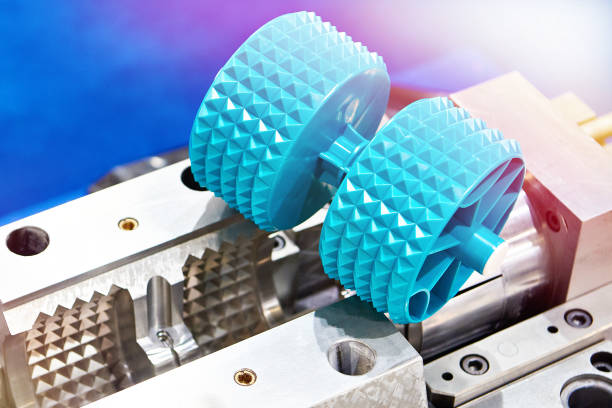

What Are Custom Mould Parts?

Custom mould parts refer to precision-engineered components tailored to fit specific design requirements. These parts are crafted using bespoke moulds that are created based on exact specifications, often after close consultation with the client. The advantage of customisation lies in its ability to meet the unique performance, material, and dimensional requirements of complex designs.For industries that need highly specialized components, such as the medical or aerospace sectors, custom mould parts offer precision and reliability that standard components cannot. Whether it's for low-volume production or a specific product series, custom moulding provides the flexibility necessary for innovation.

Applications of Custom Mould Parts

- Automotive: Custom mould parts ensure that each vehicle component fits perfectly, contributing to the overall efficiency and safety of the vehicle.

- Medical Devices: These parts are critical in manufacturing surgical tools, implants, and diagnostic devices, where precision is not just important but essential.

- Consumer Electronics: From smartphone housings to intricate internal components, precision moulding helps achieve both aesthetic appeal and functional performance.

The Role of High-Precision Mould Components in Manufacturing

What Are High-Precision Mould Components?

High-precision mould components are parts that are engineered to extremely tight tolerances, often in the range of microns. These components are used in the production of moulds and dies that must deliver consistent results during every cycle. Precision is vital in ensuring that each part produced is of the highest quality, with no room for defects that could compromise functionality.The need for high-precision mould components has surged in industries that demand the utmost quality and reliability. Components made with these moulds are designed to last longer, perform better, and meet industry regulations, all while reducing waste and cost in the long run.

Key Benefits of High-Precision Mould Components

- Consistency and Accuracy: Every component manufactured through high-precision moulding exhibits high repeatability, reducing the risk of defects and improving the overall production process.

- Reduced Waste: With precise measurements and tighter tolerances, manufacturers can avoid costly mistakes that lead to wasted materials.

- Enhanced Durability: Precision components typically exhibit improved durability and longevity, especially in high-stress environments such as automotive engines or medical equipment.

Industries Benefiting from High-Precision Mould Components

- Electronics Manufacturing: Components such as connectors, housing, and casings need precise dimensions to ensure proper fitment and functionality.

- Aerospace: Parts used in this industry need to meet the highest standards of quality, as they often operate under extreme conditions.

- Medical Devices: Surgical instruments, drug delivery devices, and diagnostic machines all depend on high-precision components to ensure safety and accuracy.

High-Precision Moulding Services: Tailored Solutions for Complex Needs

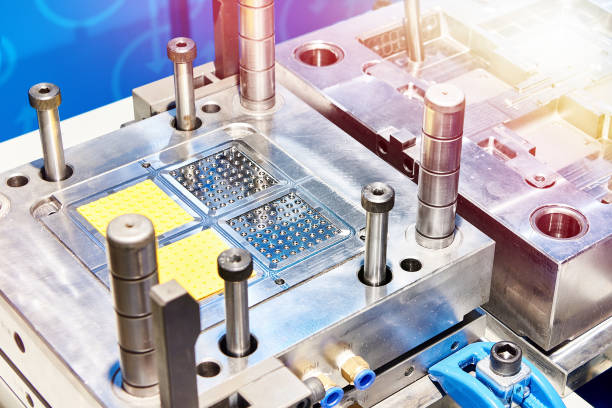

What Are High-Precision Moulding Services?

High-precision moulding services refer to the manufacturing process of creating highly accurate and durable moulded components. This process typically involves advanced technologies such as injection moulding, compression moulding, and transfer moulding, all of which are tailored to meet the specific requirements of clients. These services cater to industries that demand tight tolerances and intricate details, such as aerospace, automotive, and medical device manufacturing.

How Do High-Precision Moulding Services Work?

- Design Consultation: The process begins with a comprehensive consultation to understand the specific requirements, including material selection, part dimensions, and production volume.

- Tooling and Mould Creation: Skilled engineers design and produce custom moulds that are capable of meeting these high-precision demands.

- Production: Using advanced moulding technologies, manufacturers produce the components with exceptional accuracy and repeatability, ensuring consistent results across multiple production cycles.

- Quality Control: Rigorous testing and inspection processes are implemented to ensure that each part adheres to industry standards and client specifications.

Why Choose High-Precision Moulding Services?

- Superior Quality Control: These services employ the latest technologies and rigorous testing to ensure that each component is manufactured to the highest standards.

- Faster Turnaround Times: Thanks to advanced production methods, high-precision moulding services can deliver components quickly, reducing lead times for critical projects.

- Cost-Effective: While high-precision moulding services might initially seem costly, the long-term benefits, such as reduced wastage and fewer defects, make them highly cost-effective.

Industries That Rely on High-Precision Moulding Services

- Automotive Industry: Parts such as engine components, body panels, and safety devices all require precision moulding for optimal functionality.

- Medical Sector: Implantable devices, diagnostic tools, and surgical instruments rely heavily on high-precision moulding to ensure safety and efficacy.

- Consumer Electronics: Smartphones, wearables, and other devices require high-precision moulding for parts that need to fit together perfectly for functionality and design.

The Advantages of Using Precision Mould Parts for Production

1. Enhanced Quality and Reliability

The primary benefit of using precision mould parts is the significant improvement in product quality. These parts meet stringent industry standards and ensure that the end products perform as expected, reducing the risk of recalls or failures.

2. Increased Production Efficiency

With high-precision mould components, manufacturers can achieve higher production speeds with minimal errors. This efficiency can significantly reduce production costs and increase throughput.

3. Greater Flexibility

Custom mould parts and high-precision moulding services offer manufacturers the flexibility to develop bespoke components that meet their unique specifications. This adaptability is crucial in industries with rapidly evolving demands.

Choosing the Right Precision Moulding Partner

When selecting a precision moulding partner, several factors should be considered:

- Experience and Expertise: Look for a provider with a proven track record in creating custom mould parts and high-precision mould components for your specific industry.

- Technology and Equipment: Ensure that the company uses state-of-the-art moulding technologies that can deliver high-quality, precise components.

- Material Options: A reliable moulding partner should be able to work with a variety of materials, including metals, plastics, and composites, to suit your application.

- Customer Service: A good partner should be responsive to your needs, offering consultations and ongoing support throughout the production process.

Frequently Asked Questions (FAQs)

1. What is the difference between custom mould parts and high-precision mould components?

Custom mould parts are tailored specifically for a unique application or design, while high-precision mould components are created to meet extremely tight tolerances and dimensional requirements for high-quality production.

2. How are high-precision mould components made?

High-precision mould components are manufactured using advanced moulding techniques and technologies that ensure tight tolerances and exceptional consistency across production cycles.

3. What industries benefit most from high-precision moulding services?

Industries such as aerospace, automotive, medical devices, and consumer electronics rely heavily on high-precision moulding services to produce parts with exact specifications and high reliability.

4. How do custom mould parts improve product quality?

Custom mould parts are made to meet precise design specifications, ensuring that each component functions perfectly in the final product, reducing defects and improving overall quality.

5. What materials can be used in high-precision moulding?

High-precision moulding can be performed with various materials, including thermoplastics, metals, elastomers, and composites, depending on the specific application requirements.

6. How can I choose the best moulding service provider?

Look for a provider with extensive experience, state-of-the-art technology, and a history of producing high-quality, custom mould parts. Consider customer feedback and support options as well.

custom mould parts high-precision mould components high-precision moulding services