Hairong: Your Trusted Precision Mold Components Supplier

In the manufacturing industry, the quality and accuracy of mold components are paramount to ensuring the production of high-performance, durable products. Whether you’re creating automotive parts, electronics, or medical devices, precision mold components play a vital role in achieving the highest levels of product quality and efficiency. As a leading precision mold components supplier, Hairong is committed to providing custom precision mold components that meet the most stringent industry standards.In this article, we will explore the importance of high-precision mold parts, the process of precision mold manufacturing, and why Hairong stands out as your trusted supplier for precision injection molding components and precision mold tooling.

What Are Precision Mold Components?

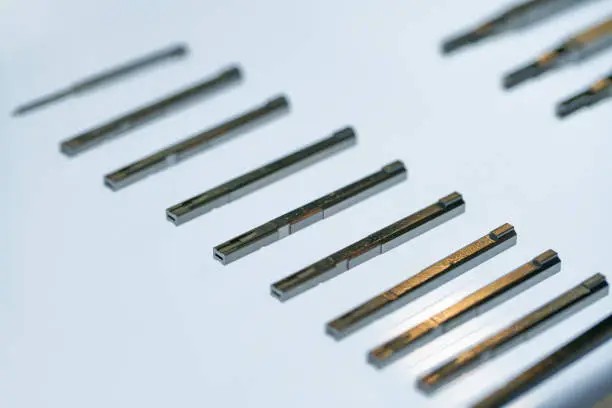

Precision mold components refer to the critical parts used in the mold-making process, which are responsible for shaping, forming, and cutting materials into desired shapes. These components are typically made from high-quality metals and require precision engineering to ensure they meet exact specifications. In industries like automotive, electronics, and medical, the need for custom precision mold components is increasing, as manufacturers strive for improved performance, reduced waste, and enhanced product quality.Hairong specializes in producing high-precision mold parts that ensure the accuracy and consistency needed for efficient manufacturing processes. By investing in advanced machinery and expert craftsmanship, Hairong guarantees that all mold components meet the required tolerances and specifications.

The Importance of Custom Precision Mold Components

Every project is unique, and the need for custom precision mold components arises when off-the-shelf mold parts cannot meet specific design or performance requirements. Custom components are essential for industries where precise engineering and high tolerances are critical.

Tailored to Specific Needs

Custom precision mold components are designed to suit the exact needs of your production process. Whether it’s for the production of complex parts or components with unique shapes and sizes, customized molds are the best solution. At Hairong, we work closely with our clients to ensure the mold components we provide match their specific technical and design requirements.

Optimizing Efficiency and Reducing Waste

Custom molds often lead to more efficient production processes. With the correct components designed specifically for a given task, manufacturers can significantly reduce material waste and production errors. By choosing custom precision mold components from a trusted supplier like Hairong, businesses can achieve greater operational efficiency and lower production costs.

High-Precision Mold Parts for Superior Performance

High-precision mold parts are essential for producing high-quality, functional end products. These parts are crafted to ensure tight tolerances and the smoothest finish, contributing to the overall performance of the mold. At Hairong, we prioritize precision in every stage of production to guarantee the performance and longevity of each component.

Applications of High-Precision Mold Parts

From precision injection molding components used in automotive manufacturing to parts for consumer electronics, high-precision mold parts are a crucial element in ensuring the reliability and durability of the final product. Some key applications include:

Automotive: Components like engine parts, dashboards, and exterior panels require precise mold parts to ensure proper fit and functionality.

Electronics: Devices like smartphones, computers, and consumer appliances rely on precision parts for high performance and longevity.

Medical Devices: Due to stringent regulatory requirements, medical device manufacturers require highly precise mold components to ensure safety and compliance.

Precision Mold Manufacturing Process

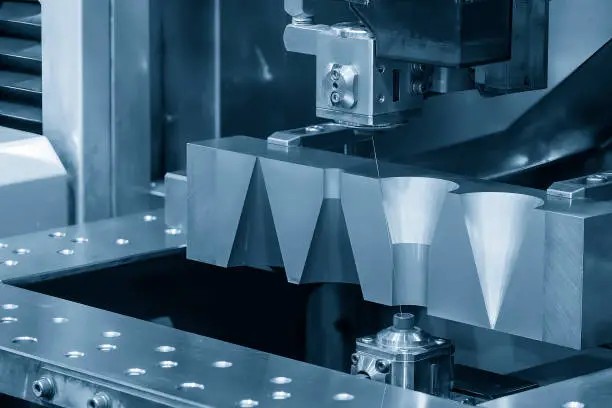

The process of precision mold manufacturing involves a series of meticulous steps designed to create molds with high accuracy and durability. Hairong employs state-of-the-art machinery and experienced engineers to ensure the quality and precision of every mold component.

Steps in Precision Mold Manufacturing

Design and Engineering: The first step is to design the mold components based on customer specifications. Advanced software tools like CAD (Computer-Aided Design) are used to create detailed 3D models of the mold.

Material Selection: The right materials are chosen based on the mold's intended application. Materials need to withstand high pressures, temperatures, and wear over time.

CNC Machining: Computer Numerical Control (CNC) machining ensures that the mold components are created with the utmost precision and tight tolerances.

Finishing and Quality Control: After the parts are machined, they undergo thorough quality control checks to ensure that they meet all design specifications and industry standards.

Hairong’s precision mold manufacturing process is designed to provide components that not only meet but exceed the requirements of the most demanding industries.

Precision Mold Tooling: The Backbone of Mold Performance

Precision mold tooling refers to the tools and equipment used to create the mold components. This includes inserts, cavities, cores, and other tooling components that play a critical role in shaping the final product. Hairong’s expertise in precision mold tooling ensures that all parts are fabricated with the highest degree of accuracy and reliability.

Importance of Precision Mold Tooling

Proper tooling is essential for ensuring that the mold components work together to produce high-quality products. High-quality precision mold tooling ensures that parts fit together perfectly, minimizing errors, defects, and downtime during the production process. With precision mold tooling from Hairong, manufacturers can expect reliable, efficient, and consistent results.

Why Choose Hairong as Your Precision Mold Components Supplier?

As a leading precision mold components supplier, Hairong offers a range of benefits that set us apart from the competition:

1. Expertise and Experience

With years of experience in the mold manufacturing industry, Hairong has built a reputation for delivering high-precision mold parts that meet the highest industry standards. Our team of skilled engineers and technicians ensures that every mold component is manufactured with precision and care.

2. Customization Capabilities

At Hairong, we understand that every project is different. That’s why we offer custom precision mold components tailored to your exact specifications. Whether you need components for complex molds or specialized applications, we can design and produce molds that meet your unique needs.

3. State-of-the-Art Technology

We utilize the latest CNC machinery, CAD software, and high-precision tooling equipment to ensure that every precision injection molding component we produce is of the highest quality. Our advanced technology ensures that your molds will perform consistently and reliably throughout their lifecycle.

4. Quality Assurance

Hairong places great emphasis on quality assurance at every step of the manufacturing process. We conduct rigorous inspections to ensure that all precision mold components meet your specifications and are free from defects. With our quality control processes, you can trust that your molds will perform optimally in your production processes.

5. On-Time Delivery

We understand the importance of timely delivery in the manufacturing industry. Hairong’s efficient production processes and strong supply chain management allow us to deliver precision mold components on schedule, ensuring that your projects stay on track.

As the demand for precision mold components continues to grow across industries, Hairong stands out as a leading precision mold components supplier. Whether you’re in need of custom precision mold components, high-precision mold parts, or precision injection molding components, we provide the expertise, technology, and customer service you need to take your manufacturing processes to the next level.Choose Hairong for all your precision mold tooling and precision mold manufacturing needs, and experience the difference of working with a trusted industry leader committed to excellence and innovation.

precision mold components high-precision mold parts precision injection molding components