What Are the Essential Steps in Precision Mold Part Manufacturing?

Precision mold part manufacturing is a complex process that demands high accuracy, meticulous attention to detail, and advanced technology. It is the cornerstone for industries requiring precision mold components, from automotive to electronics. If you're looking for a reliable precision mold components manufacturer or seeking insights into how a precision mold parts components factory operates, this guide outlines the essential steps involved in the process.

1. Design and Conceptualization

Every project begins with a detailed design. Using CAD (Computer-Aided Design) software, manufacturers create accurate blueprints of the required precision mold parts components. This stage is critical as it sets the foundation for the manufacturing process. Experienced engineers and designers collaborate to ensure that the design meets functional and structural requirements.

2. Material Selection

Choosing the right material is crucial for producing high-quality mold parts. Common materials include tool steel, stainless steel, and hardened alloys. The choice depends on factors like durability, heat resistance, and application requirements. Precision mold parts components factories often have a wide range of materials to meet diverse client needs.

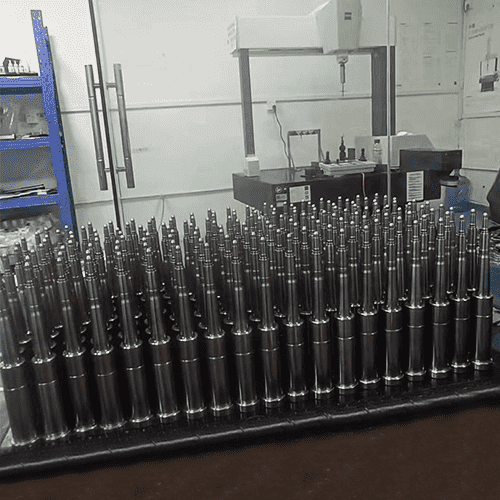

3. CNC Machining and Milling

Once the design is finalized and materials are selected, the actual manufacturing begins. CNC (Computer Numerical Control) machining and milling are employed to cut, shape, and refine the mold components. These advanced technologies ensure precision and minimize errors, which is why a reputable precision mold components manufacturer invests heavily in cutting-edge equipment.

4. Heat Treatment

Heat treatment strengthens the mold components by enhancing their hardness and durability. This step is vital for parts that will endure high stress or extreme temperatures. Factories specializing in precision mold parts components typically perform this process in-house to maintain quality control.

5. Surface Finishing

Surface finishing ensures the mold parts have the desired texture and appearance. Techniques such as polishing, grinding, and coating are applied to achieve a flawless finish. A smooth surface not only improves the part's functionality but also extends its lifespan.

6. Quality Control and Inspection

No precision mold parts components leave the factory without thorough quality checks. Advanced measurement tools like CMM (Coordinate Measuring Machines) and optical scanners are used to verify dimensional accuracy and adherence to specifications. A reputable precision mold components manufacturer prioritizes stringent quality assurance to deliver defect-free products.

7. Assembly and Delivery

Finally, the precision mold components are assembled and prepared for shipment. Timely delivery and excellent packaging ensure that the components reach clients in perfect condition, ready for integration into their production systems.

Precision mold part manufacturing is a multi-step process that requires expertise, advanced technology, and strict quality control. Whether you’re partnering with a precision mold components manufacturer or sourcing from a precision mold parts components factory, understanding these steps helps you appreciate the craftsmanship and technology involved in creating these critical components. With the right manufacturer, you can ensure that your mold parts meet the highest standards of precision and reliability.

Precision Mold Components manufacturer Precision Mold Parts Components Precision Mold Parts Components factory