Why Is Maintenance Important for Bottle Cap Mold Accessories?

Bottle cap mold accessories play a critical role in ensuring efficient production, consistent quality, and long-lasting performance in the manufacturing of bottle caps. Despite their durability, regular maintenance is essential to maximize their lifespan and maintain production efficiency. In this article, we will explore the importance of maintenance for bottle cap mold accessories and provide insights into the benefits of proactive care. We'll also highlight key SEO keywords such as bottle cap mold parts, custom bottle cap molds, and bottle cap production efficiency to help businesses better understand and implement effective maintenance strategies.

1. The Role of Bottle Cap Mold Accessories

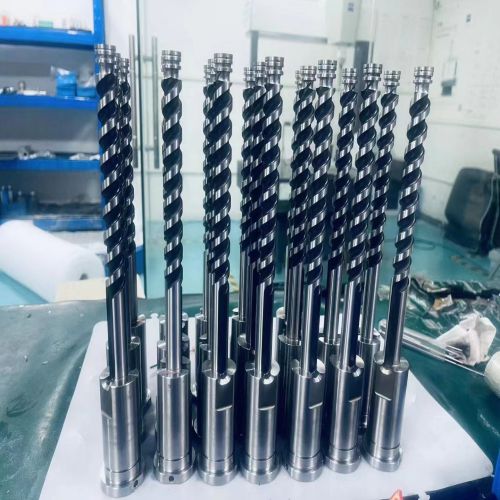

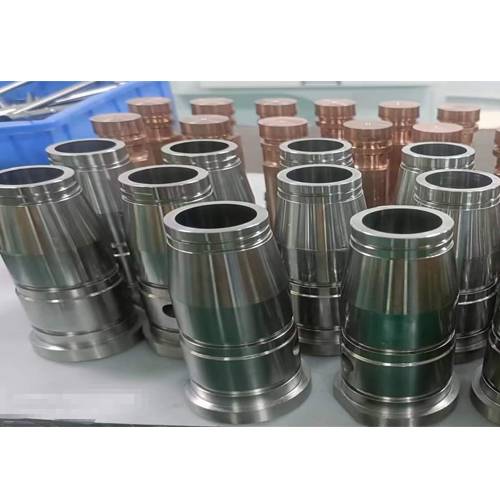

Bottle cap mold accessories are the components that support the functionality of the mold, including ejector pins, cooling systems, cavity inserts, and alignment guides. These parts ensure precision, efficiency, and consistency during the production process. Whether you are using standard molds or custom bottle cap molds, the accessories are vital to achieving high-quality output. Neglecting maintenance of these parts can lead to inefficiencies, increased downtime, and potential damage to the mold itself. As a result, regular upkeep is crucial for sustaining bottle cap production efficiency and minimizing operational costs.

2. Key Benefits of Maintaining Bottle Cap Mold Accessories

Improved Production Efficiency

Properly maintained mold accessories ensure that the molding process runs smoothly. Worn or damaged components can cause production delays or defects, ultimately affecting the overall productivity of your operation. Regular inspections and maintenance help identify issues early, keeping the bottle cap production efficiency at its peak.Consistent Product Quality

The precision of bottle caps is heavily dependent on the condition of the mold accessories. Damaged or misaligned parts can lead to defects such as uneven caps, poor threading, or improper sealing. Maintenance ensures that the mold accessories remain in optimal condition, allowing for consistent and high-quality production.Extended Lifespan of Mold Components

Maintenance helps prevent premature wear and tear of mold accessories. Regular cleaning, lubrication, and part replacement as needed can significantly extend the lifespan of both standard and custom bottle cap molds. This reduces the need for frequent replacements, saving your business money in the long run.Reduced Downtime

Unscheduled maintenance or emergency repairs can cause significant downtime, disrupting production schedules. Proactive maintenance minimizes the risk of unexpected failures, ensuring that your production line operates without interruptions.Cost Savings

While maintenance requires an upfront investment of time and resources, it prevents costly repairs or replacements in the long term. Ensuring the durability and reliability of your bottle cap mold parts means fewer unexpected expenses and a better return on investment.

3. Common Maintenance Practices for Bottle Cap Mold Accessories

Regular Cleaning

Dust, debris, and residual materials can accumulate on mold accessories, affecting their performance. Routine cleaning prevents buildup that can lead to defects or equipment damage.Lubrication

Moving parts such as ejector pins and guides require proper lubrication to reduce friction and prevent wear. Regular application of the appropriate lubricant is essential for maintaining smooth operation.Inspection and Monitoring

Frequent inspections of bottle cap mold parts can help detect early signs of damage or wear. Using tools like microscopes or ultrasonic testing can aid in identifying issues that are not visible to the naked eye.Timely Replacement

Some accessories, like seals or inserts, have a limited lifespan due to continuous use. Replacing these parts as needed ensures that the mold operates at peak efficiency.Temperature Control Checks

The cooling system is a vital part of any mold, as it prevents overheating during production. Ensuring proper function of the cooling channels and monitoring temperature fluctuations helps maintain production consistency.

4. Why Businesses Should Prioritize Maintenance

Whether you are producing bottle caps for beverages, pharmaceuticals, or cosmetics, the condition of your custom bottle cap molds and accessories directly impacts your bottom line. Neglecting maintenance not only reduces efficiency but also increases the likelihood of production errors and costly downtime. For businesses looking to stay competitive in the industry, maintaining bottle cap mold parts is a non-negotiable aspect of operations. It also aligns with sustainability goals, as well-maintained equipment reduces material waste and energy consumption during production.

Conclusion:

Maintenance of bottle cap mold accessories is more than just a routine task—it is a strategic approach to ensuring smooth operations, consistent product quality, and cost-effective production. By proactively caring for your bottle cap mold parts, you can enhance bottle cap production efficiency, extend the lifespan of your equipment, and minimize operational costs. Whether you rely on standard molds or invest in custom bottle cap molds, prioritizing maintenance is the key to achieving long-term success in the bottle cap manufacturing industry. Make maintenance a regular part of your production schedule and watch your business reap the rewards of improved performance and reliability.

bottle cap mold parts custom bottle cap molds bottle cap molds supplier