How to ensure the accuracy of dimensions during the processing of mold accessories?

In the processing of mold accessories, ensuring dimensional accuracy can be achieved through the following aspects:

Accurate design and planning: Before processing, detailed and accurate design should be carried out based on the product's requirements and usage needs, clarifying the dimensions, tolerances, and positional tolerances of each part.

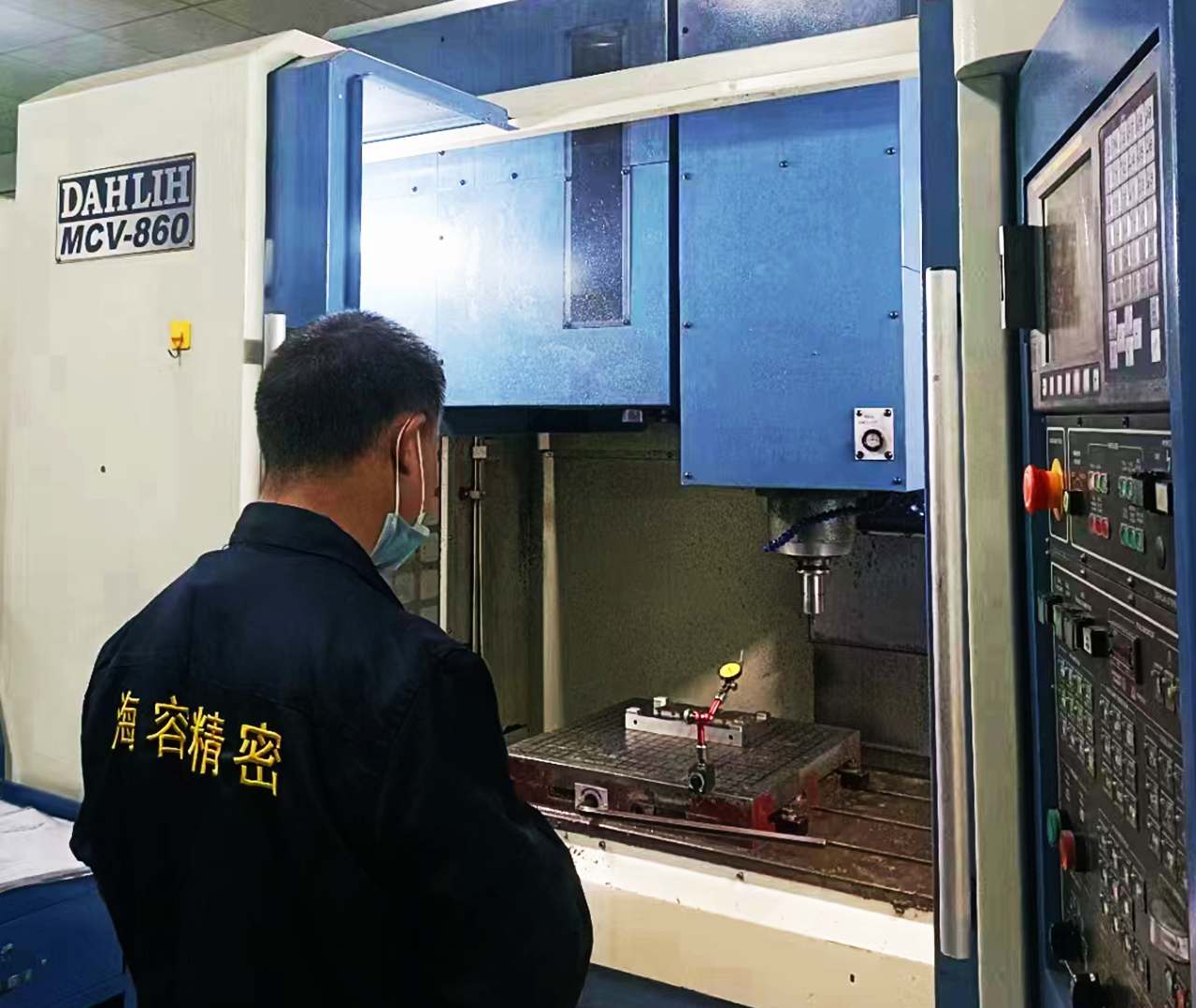

Choose high-precision machining equipment such as CNC machines, EDM machines, wire cutting machines, etc., which can provide higher machining accuracy and stability.

Selection of cutting tools and fixtures: Choose suitable cutting tools and high-quality fixtures to ensure accurate positioning and firm clamping of the workpiece during the machining process, reducing dimensional deviations caused by tool wear and clamping errors.

Strict process control: Develop a reasonable machining process route, including optimization of cutting parameters (such as cutting speed, feed rate, cutting depth), and reasonable arrangement of machining sequence.

Measurement and inspection during the process: During the machining process, high-precision measuring tools such as micrometers, vernier calipers, coordinate measuring instruments, etc. are frequently used to measure and monitor the machining dimensions in real time, detect and correct deviations in a timely manner.

Temperature control: Temperature changes during the processing may affect the size of the workpiece, so effective cooling measures should be taken to control the processing temperature and reduce thermal deformation.

Skills and experience of operators: Operators should have rich processing experience and professional skills, be proficient in operating equipment, and make correct judgments and handling of abnormal situations during the processing.

Quality Control System: Establish a comprehensive quality control system, conduct strict inspections and checks on raw materials, processing, and finished products to ensure that products meet precision requirements.