How Do High Precision Mold Slider Inserts Improve Production Quality?

In the world of manufacturing, achieving consistent, high-quality results is paramount. High precision mold slider inserts play a significant role in enhancing production quality, particularly in complex injection molding processes. This article explores how these specialized components contribute to superior production standards while incorporating insights about customized high precision mould inserts, injection mold slider manufacturers, and high quality precision injection molds.

Enhanced Accuracy and Consistency

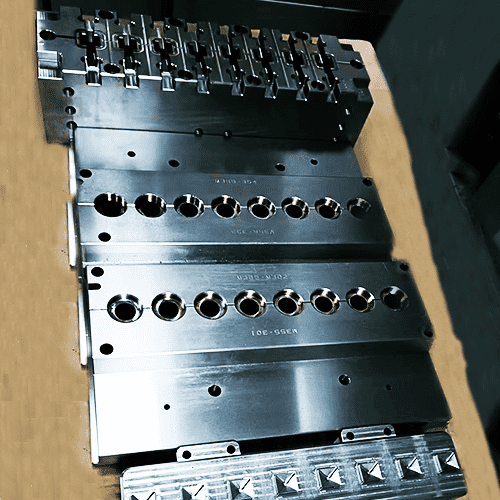

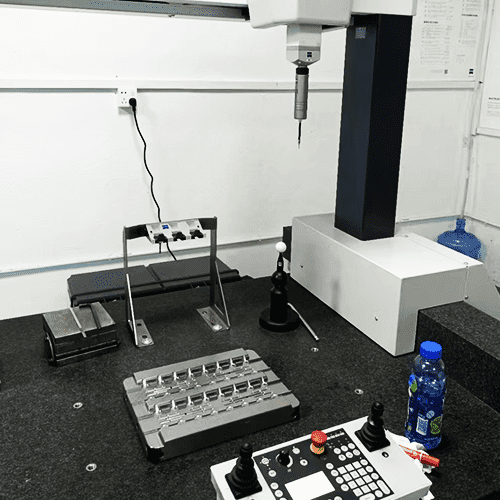

The primary advantage of using high precision mold slider inserts is the accuracy they bring to the molding process. Customized high precision mould inserts are designed to fit perfectly within the mold cavity, ensuring seamless movement and alignment during the injection cycle. This precision translates to consistent part quality, reduced defect rates, and tighter tolerances that are crucial for high-end applications. Injection mold slider manufacturers understand that even slight deviations in slider performance can lead to misaligned parts or uneven surfaces. By utilizing high-quality materials and advanced manufacturing techniques, these manufacturers produce mold slider inserts that maintain their precision over repeated cycles, thus sustaining production quality over time.

Improved Durability and Reduced Maintenance

High precision mold slider inserts made with superior materials offer enhanced durability. This is essential for high-quality precision injection mold processes where reliability and longevity are key. Durable sliders resist wear and tear, reducing the need for frequent maintenance or part replacements.

With customized high precision mould inserts, manufacturers can tailor the design to specific requirements, optimizing the performance for particular applications. This customization minimizes friction and wear, resulting in a longer lifespan for both the slider and the mold.

Complex Geometries Made Possible

Another significant benefit of using high precision mold slider inserts is their capability to facilitate the production of complex part geometries. The inclusion of a precisely designed slider allows the mold to achieve intricate shapes that would otherwise be impossible or inefficient. This expands the range of products that high quality precision injection molds can produce, catering to industries such as automotive, aerospace, and consumer electronics, where precision and complexity are essential.

Efficiency and Cost Savings

Precision mold slider inserts contribute to overall efficiency by enabling smoother operations and minimizing cycle times. Injection mold slider manufacturers employ advanced technologies to ensure these components move seamlessly within the mold, preventing downtime caused by jamming or misalignment.

When molds perform consistently without disruptions, production runs become more efficient, leading to cost savings. Companies benefit from reduced waste and increased output, making high precision slider inserts a sound investment.

Final Thoughts:

High precision mold slider inserts are more than just components—they are crucial elements that influence the success of injection molding projects. By partnering with reliable injection mold slider manufacturers and opting for customized high precision mould inserts, companies can ensure that their high quality precision injection molds produce parts that meet stringent quality standards while maximizing efficiency and durability. Investing in these specialized inserts is a strategic move for any manufacturer aiming to stay competitive and produce flawless products.

customized high precision mould insert injection mold slider manufacturers high quality precision injection mold